Unlocking a New Level of Comfort and Convenience

Interior auto lighting provides a new level of comfort and convenience by enhancing the overall ambiance and functionality of the vehicle's interior. It helps improve visibility during nighttime driving, making it easier to locate and access controls and compartments. Additionally, interior auto lighting can create a pleasant atmosphere, adding a touch of luxury and personalization to the vehicle's interior.

From accents to indicators, LEDs can be found throughout the cabin for systems, including:

- Storage areas

- Trunks

- Car doors

- Overhead

- Glove boxes

- Reading lights for backseat passengers

Engineers and OEMs can leverage flexibility in designing interior lighting to enhance comfort and convenience during driving. By carefully considering the placement, color, and color temperature of LEDs, they can create an ambiance that positively affects mood and contributes to an improved driving experience.

Because several lighting systems are located all over the inside of a vehicle, component size, energy efficiency, and thermal performance are key.

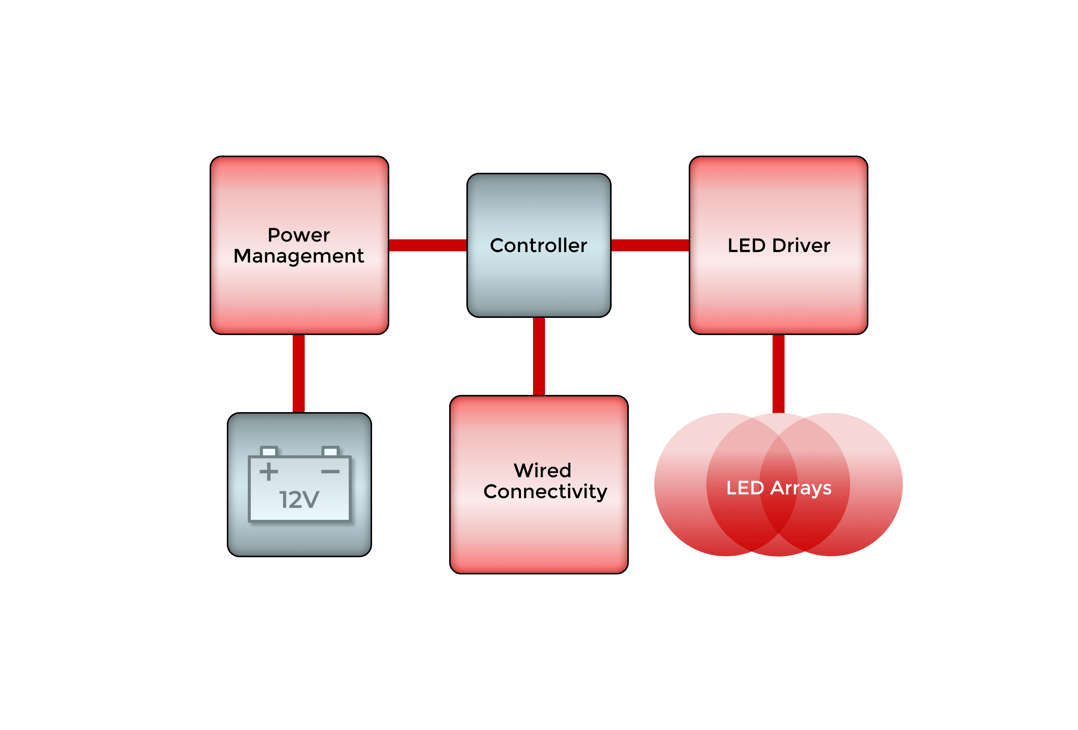

How does automotive interior lighting work?

Power from the vehicle’s battery is converted from a higher voltage to 12V-48V via a DC-DC converter. This smaller voltage is used to power the interior lighting module, which may also be connected to several other systems within the vehicle, including ADAS.

A MOSFET is used to safeguard the components from reverse polarity should the current move backward from the Schottky diode to the battery.

Each LED module consists of a controller wired to the vehicle and an LED driver that executes the desired actions for the LED arrays after receiving instructions from the controller. The driver may provide constant current to power the LEDs when dimming and performing other functions, or they can utilize pulse with modulation (PWM).

The CAN/LIN bus helps these inputs and outputs communicate with each lighting module and the other systems. It's protected with an ESD diode to minimize electrostatic discharge.

Interior Auto Lighting Block Diagram

Design & Engineering Considerations

- Thermal performance - proper heat dissipation techniques are required to eliminate safety hazards and improve overall efficiency

- Low reverse recovery time - can provide battery reverse protection and reduce EMI while enhancing efficiency

- Reliability in harsh environments - many of the lights inside a vehicle are related to safety, so they perform without fail in a range of conditions and high temperatures

- Stable LED control for dimming - the power supply must be able to support dimming functionalities whether constant current or pulse with modulation (PWM) is used

- Component footprint - because several lighting systems are utilized throughout a vehicle’s cabin, taking up as little room as possible is crucial

- Low on-resistance - enhances performance through optimized light output and efficiency

- High current handling - certain applications, such as ambient and reading lights, may require high-current drivers

- Efficiency - LEDs are inherently efficient, but interior auto lighting designs should minimize power losses and wasted energy

- Design flexibility - enable the control of individual LEDs to maximize functionality while taking up less component space and being able to integrate with various lighting systems

- Switching speed - near real-time status indication and lighting are required to enhance safety

- Applicable industry standards- stringent quality and reliability standards must be met for all automotive components, including AEC-Q

Recommended Products

Power Management

Schottky Barrier Rectifier:

|

Schottky Barrier Rectifier:

|

Schottky Barrier Rectifier:

|

Battery Reverse Protection

Power MOSFET:

|

Power MOSFET:

|

|

Motor Control/LED Driver

Power MOSFET:

|

Power MOSFET:

|

|

Power MOSFET:

|

Power MOSFET:

|

|

CAN/LIN Bus Protection

ESD Protection:

|

ESD Protection:

|

ESD Protection:

|

Interior automotive lighting plays a significant role in safety, comfort, and ambiance. Implementing design best practices will help ensure a reliable operation for the long haul.

Explore MCC Semi’s diverse solutions for auto and EV applications, including:

Body Control Module (BCM)

Infotainment

Instrument Cluster

Exterior Lighting

On-board Charger (OBC)

EV Charging Station

Battery Management System (BMS)

DC-DC Converter

Electric Power Steering (EPS)

Advanced Driver Assistance System (ADAS)

Seat Control

Have questions or need assistance? Use the MCC website chatbot to contact us.

.png?width=50&height=50&name=mcc%20150x150%20(1).png)

%20(1).png)