Enhancing Safety and Simplifying Operation

A mainstay in modern vehicles, electric power steering (EPS) systems improve overall vehicle handling while providing opportunities for more advanced safety features compared to their hydraulic power steering counterparts.

EPS systems utilize a small electric motor and sensors to gauge how much torque, or effort, the driver is applying to the wheel at the time, then adjusts the power level accordingly. Benefits include:

- Slight fuel economy compared to hydraulic power steering

- Reduced maintenance compared to hydraulic fluid replacement

- Enables a variety of modern features we rely on — from lane assist to parking

As vehicles continue to get smarter and more helpful for drivers—even to the point where they drive themselves—EPS technology is a crucial factor. This advanced system is transforming the way we think about steering. It uses an electric motor to precisely control and assist vehicle steering, providing an optimal and enjoyable driving experience.

Key Features of EPS in Automated Driving:

- Versatility Across Vehicle Types: EPS is designed to meet the needs of a wide range of vehicles, from small and mid-range cars to sports models and light commercial vehicles. This adaptability ensures that no matter the vehicle type, the steering system can deliver enhanced control and assistance.

- Enhanced Safety: The latest generation of EPS units includes sophisticated control systems that maintain security even in the event of an error. This is particularly important as vehicles become more autonomous, ensuring that safety is never compromised.

- Support for Automation: With an electric interface built to handle highly automated driving tasks, EPS is ready to support automation levels up to SAE-Level 4. This means that the steering system is equipped to handle complex driving environments, paving the way for future innovations in driver-assistance technologies.

By integrating these advanced features, EPS not only contributes to a seamless and safe driving experience but also plays an essential role in the evolution towards fully automated vehicles.

How does EPS work?

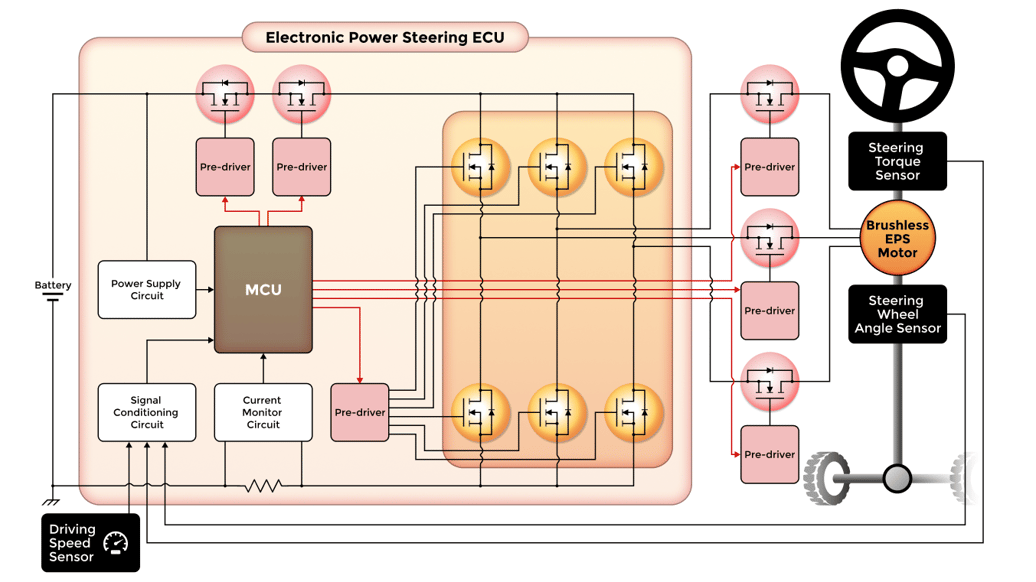

A small motor is installed on the steering rack or steering column, with several strategically placed sensors to detect the torque being applied by the driver. Together, these components increase or decrease power to help the driver steer based on the inputs of the driver’s torque, speed, and other data from the sensors. At lower speeds, the steering wheel can be turned effortlessly. At higher speeds, it requires a little more resistance to give the feel of control.

The Electronic Power Steering (EPS) system goes a step further by integrating an intelligent electric motor that works in tandem with a control unit. This unit receives signals from the torque sensor and calculates the optimal steering support needed. It then communicates with the electric motor to deliver precise assistance, ensuring the steering is responsive and adaptive.

- Automated Feedback Loop: The control unit’s ability to process real-time data and adjust steering assistance exemplifies automation, making the vehicle more intuitive and easier to handle.

- Enhanced Driving Experience: By providing the necessary resistance at higher speeds and ease at lower speeds, the EPS system not only enhances safety but also aligns with the automated driving goals, seamlessly blending manual and automated steering controls.

The diagram below shows a brushless DC (BLDC) motor being utilized in the EPS system. BLDCs are relatively compact and cost-effective while delivering the benefits of long-lasting performance, easy installation, and reduced EMI noise.

In essence, as vehicles move towards greater automation, the EPS system plays a pivotal role by intelligently facilitating the transition, ensuring that driving remains smooth and controlled regardless of speed or road conditions.

Design considerations:

- Energy efficiency - lower energy usage enhances fuel economy and requires less power from the vehicle’s battery, which improves the range for EVs.

- High-temperature capability - components must be able to withstand the worst-case scenario in thermal surges.

- High current handling - the system should perform reliably under the worst possible conditions and current surges.

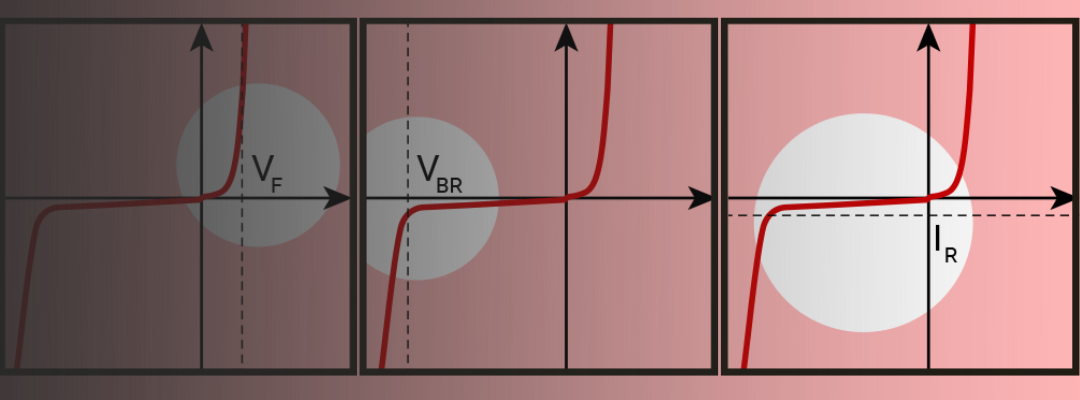

- Low on-resistance - minimizing heat generated during operation extends the life of the component, and low RDS(on) plays a crucial role while enhancing system responsiveness.

- Fast switching speed - switching should be fast enough to ensure smooth operation amid ever-changing conditions.

- Low reverse recovery time - low Trr is needed to enable faster switching at high frequencies and improve efficiency.

- EMI protection - proper suppression and filtration are needed to reduce noise and electromagnetic interference.

- Applicable industry standards - to ensure maximum safety and reliability, adherence to AEC-Q101 and other standards is required for certain components.

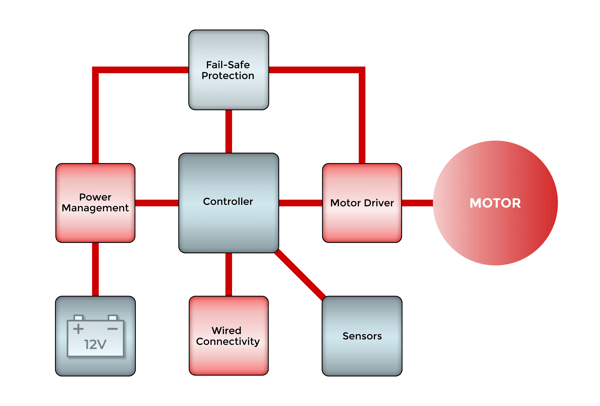

EPS Block Diagram

Recommended Products

Power Management |

||

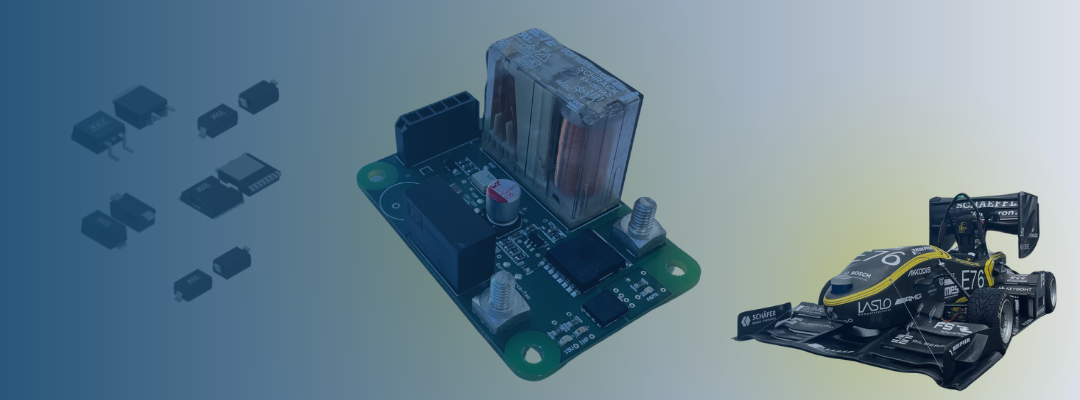

Schottky Barrier Rectifier: SS110Q-L

|

Schottky Barrier Rectifier: SK210Q-L

|

Schottky Barrier Rectifier: SK310Q

|

Battery Reverse Protection |

||

Power MOSFET: MCACL320N04YQ

|

Power MOSFET: MCG53N06AHE3

|

|

Motor Control |

||

MOSFET: MCACL320N04YQ

|

MOSFET: MCU75N06YHE3

|

|

CAN/LIN Bus Protection |

||

ESD Protection: ESD1524D3BHE3A

|

ESD Protection: ESD24VD3BHE3

|

ESD Protection: ESDSB5V0D3BHE3

|

Electric power steering is one of many automotive systems that require effective design for safe, reliable operation. From electrification to powertrain and beyond, MCC provides quality, cost-effective solutions to help you reach your design goals. The EPS system does more than just assist with steering; it integrates seamlessly with various vehicle parameters through an intelligent steering concept. This concept incorporates an electronic control unit and innovative software, establishing a robust foundation for connectivity with other vehicle systems and components.

By facilitating this integration, EPS enhances not only the steering but also the overall performance and safety of the vehicle. It's a pivotal element in modern automotive design, ensuring that all systems work together harmoniously to deliver a superior driving experience.

Explore our robust portfolio designed for excellence in automotive design:

On-board Charger (OBC)

EV Charging Station

Battery Management System (BMS)

DC-DC Converter

Advanced Driver Assistance System (ADAS)

Have questions? Use the MCC website chatbot for fast, convenient support.

.png?width=50&height=50&name=mcc%20150x150%20(1).png)

%20(1).png)