Essential Components for Stable, Efficient Power Delivery

Alternating current (AC) is the global standard for transmitting power over long distances. Its ability to minimize energy loss across transmission lines makes it ideal for distribution. However, most electronic devices—from consumer gadgets to industrial control systems—depend on clean, consistent direct current (DC) to operate.

This mismatch creates a crucial design requirement: converting AC into DC with precision and reliability. At the center of this process is the rectifier diode.

MCC provides a broad portfolio of rectifier diodes that ensure this critical conversion takes place efficiently. From low-voltage electronics to high-power industrial systems, MCC rectifiers are built to deliver consistent performance and long-term reliability.

The Role of Rectifier Diodes in Power Systems

Rectifier diodes perform two fundamental actions that enable AC to DC conversion:

- Half-Cycle Conduction: It permits only the positive phase of the AC waveform to pass through, effectively "clipping" the negative cycle.

- Unidirectional Flow: It enforces one-way current movement, preventing any backward flow that could disrupt DC stability.

Figure 1: Standard Diode Schematic Symbols

Understanding the Rectifier Response Curve

The electrical response curve of a rectifier diode provides valuable insight into its behavior under real-world operating conditions. It illustrates how the device conducts current in the forward direction and blocks it in reverse, which are key performance traits for AC to DC conversion.

An ideal response curve features three critical characteristics:

- Steep forward conduction for low resistance and efficient current flow

- Flat reverse baseline to ensure strong blocking capability

- High breakdown voltage (VBR) for resilience against voltage transients

This curve helps engineers evaluate performance, identify limitations, and select the right diode for specific system requirements.

How Rectifier Diodes Work: Three Core Characteristics

Rectifier diodes support stable power conversion through a set of well-defined electrical behaviors. These core traits govern how the device functions under load and determine its suitability for different applications. Understanding these characteristics is essential when selecting the right diode for performance-critical designs.

Figure 2: Core Principles of Rectifier Diode Operation

Figure 2: Core Principles of Rectifier Diode Operation

These characteristics form the foundation of rectifier performance in both standard and high-efficiency designs.

MCC Rectifier Technologies

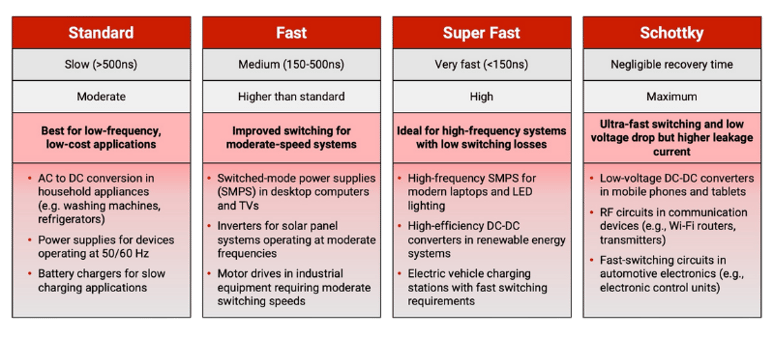

MCC classifies its rectifier diodes by switching speed, forward voltage behavior, and recovery performance. Each technology is optimized for specific application demands.

- Standard recovery diodes: Low-cost, general-purpose rectification in mains-frequency applications such as linear power supplies, battery chargers, and welding equipment.

- Fast recovery diodes offer reduced reverse-recovery charge and moderate switching speed, making them well suited for snubber circuits, motor drives, and mid-frequency switch-mode power supplies.

- Super fast recovery diodes provide high-speed switching with minimal recovery loss, and are commonly used in high-frequency converters, power factor correction stages, and resonant power supplies.

- Schottky barrier diodes deliver near-zero recovery time and very low forward voltage drop. These are ideal for low-voltage, high-efficiency applications including DC-DC converters, OR-ing functions, switch-mode supply outputs, and reverse polarity protection.

Figure 3: Rectifier Technology Categories

Diverse Package Options for Design Flexibility

MCC offers over 1,300 rectifier SKUs across automotive-grade and non-automotive solutions. Devices are available in various package types to meet design and power density constraints:

- Through-hole packages support high-current designs with robust mechanical reliability

- Axial leaded formats are suitable for traditional PCB layouts

- Surface-mount (SMD) options provide compact, high-efficiency integration for tight board spaces

Figure 3: Axial, Leaded & Through-Hole Package Examples |

Figure 4: SMD Package Leaded and Leadless Examples |

A detailed heatmap of package options—covering size, thermal performance, and current capacity—is available in Rectifier Diodes Explained: A Complete Engineer’s Guide to Types and Applications.

MCC Rectifier Product Highlights

MCC offers over 1,300 rectifier devices, covering four key types: standard recovery, fast recovery, super fast recovery, and Schottky barrier rectifiers. The portfolio supports a wide range of voltages from 15 volts up to 4000 volts and current ratings from 0.5 ampere to 100 amperes.

- MCC rectifiers are used across many real-world applications, including power supplies, battery chargers, UPS systems, motor drives, welding machines, RF equipment, ESD protection, and DC to DC converters.

- To support different assembly and layout requirements, MCC provides both through-hole and surface-mount options in widely adopted packages such as SOD-123, SMA, SMB, SMC, DPAK, D2PAK, TO-220, and TO-247. Leaded and leadless versions are available to meet varying design needs.

- For automotive and high-speed switching applications, MCC offers AEC-Q qualified rectifiers, including super fast recovery devices with reverse recovery times below 150 nanoseconds, and Schottky rectifiers that feature low forward voltage to improve efficiency and reduce EMI.

Rectifier Diode Functions and Application Areas

MCC rectifier diodes are a core component in a wide range of circuit functions and end applications. They are commonly used to convert AC to DC in power supplies, battery chargers, UPS systems, motor drives, and welding machines. In high-frequency designs, MCC offers super fast and Schottky barrier rectifiers for switching power supplies and DC-DC converters.

These rectifiers are also designed into RF equipment for signal demodulation, ESD protection circuits, and OR-ing applications for backup source isolation. They function as freewheeling diodes to suppress back-EMF in motors and coils, and as protection devices against reverse polarity in battery-powered designs.

Application areas include power supplies for industrial automation, consumer electronics, vehicle electrical systems, communication and control modules, and AC to DC wall adapters and chargers.

Design with Reliability in Mind

Power systems are only as dependable as their conversion components. Selecting the right rectifier early in the design process reduces the risk of instability, thermal failure, and costly late-stage redesigns. MCC rectifiers provide the thermal efficiency, surge handling, and electrical robustness needed to protect your system at the source.

Power Up with Confidence

Rectifier diodes are at the core of every reliable power delivery system. MCC offers a complete range of rectifier solutions to support your AC to DC conversion needs. Whether you’re designing for high current, limited space, or extreme voltage conditions, MCC provides the flexibility and performance you can count on.

Explore MCC’s full rectifier portfolio or contact our team for design support, sample requests, and package selection guidance.

Ready to go deeper? Access our complete engineering guide: Rectifier Diodes Explained: A Complete Engineer’s Guide to Types and Applications.

.png?width=50&height=50&name=mcc%20150x150%20(1).png)