Key Considerations for Reliable Performance

Automotive body control modules (BCMs) manage a range of features designed to enhance driver safety. As driving and environmental conditions change, wipers, interior and exterior lighting, mirrors, locks, thermostats, and windows need to keep pace with the operator’s commands.

How does a body control module work?

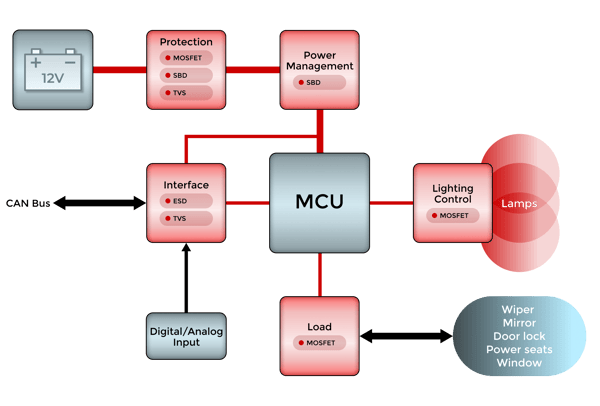

The Body Control Module (BCM) functions as a central hub for managing vital vehicle systems. It processes inputs from sensors and switches through the microcontroller unit (MCU), which then controls load drivers to activate output devices. Connectivity is managed via a CAN/LIN bus, allowing the MCU to handle both analog and digital inputs. The BCM also oversees lighting systems for status indications and driver communications, and it may connect to the instrument cluster or other internal systems. By facilitating communication with other onboard computers, the BCM enables multiple vehicle functions without extensive wiring. This seamless integration is crucial for modern BCM designs.

Efficient inter-system communication enhances vehicle performance and reliability by streamlining operations and reducing complexity. This approach not only simplifies the architecture but also minimizes potential failure points, making vehicles more intelligent and responsive to user needs. Such integration is foundational in contemporary automotive design, driving innovations that emphasize functionality and simplicity.

A comprehensive BCM solution comprises several key components:

- LDOs (Low Dropout Regulators): Provide a stable power supply.

- CAN and LIN Networking: Enable robust in-vehicle communication.

- Limp Home Functionality: Allows limited operation during system failures, ensuring safe relocation.

- High-Side Switches: Efficiently manage electrical power distribution.

These elements work together to ensure the vehicle operates smoothly, safely, and efficiently, integrating complex functionalities within a single module.

BCM Block Diagram

Engineering & Design Considerations

- Safety - because the BCM manages several functions essential to the safe operation of the vehicle, unreliable components aren’t an option. Additionally, open-load and short-circuit detection are crucial to prevent system failures and ensure overall vehicle safety.

- Processing speed & response times - although multiple ECUs and systems must communicate and be processed in the BCM, these events need to happen in real time, so speed is crucial. Effective communication between domains ensures that all systems are synchronized for optimal performance.

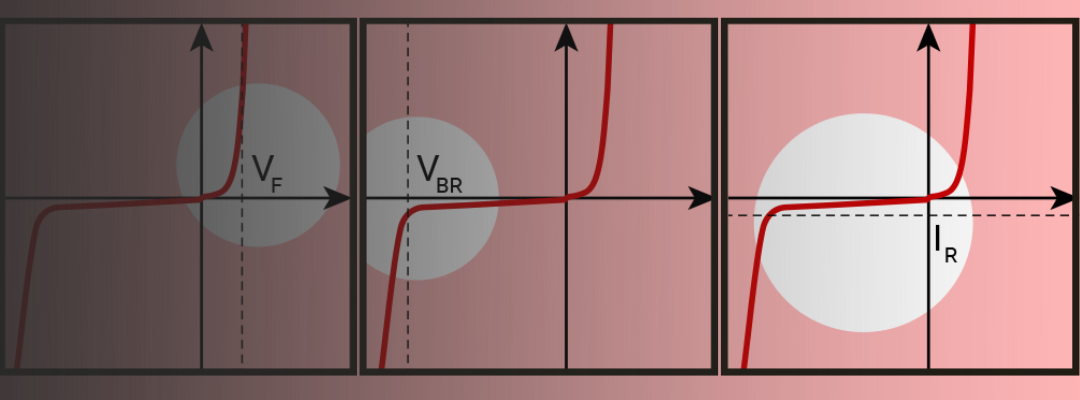

- Reverse battery protection - protective diodes should be included to prevent damaging reverse voltage in the battery. This ties into the broader need for robust protection mechanisms within the BCM design.

- Overvoltage protection - transients and power surges do happen in auto applications, so the body control module parts should incorporate those into the design. Optimizing for battery transients and preventing electromagnetic interference (EMI) are key to maintaining system integrity.

- Efficiency - powered by the vehicle’s battery, which also powers all other electrical systems, the BCM should operate as efficiently as possible. This includes replacing traditional relays and fuses to reduce size and improve power efficiency.

- ESD protection - electrostatic discharge can impact the reliability of the BCM and its components, so protection measures must be in place. Improved thermal efficiency through optimized PCB layout further enhances the BCM's durability and performance.

- Applicable industry standards - all components must adhere to strict automotive industry guidelines, including AEC-Q101, ensuring that each part meets quality and reliability standards required in modern vehicles.

Recommended Products

Integrated Circuits and Reference Designs for BCMs Our comprehensive solutions for automotive body control modules (BCMs) integrate a variety of essential components, ensuring robust and efficient performance. These solutions encompass advanced LDOs, CAN and LIN in-vehicle networking capabilities, limp home functionality, and high-side switches, providing a complete BCM framework.

Protection |

||

Power MOSFET: MCAC80P06YHE3

|

Schottky Barrier Rectifier: SMD110PL

|

TVS: SMA6J14CAHE3

|

Power Management |

||

Schottky Barrier Rectifier: SK36BQ-L

|

Schottky Barrier Rectifier: SS24Q-L

|

Schottky Barrier Rectifier: SMD16PLQ

|

Schottky Barrier Rectifier: SMD36HE1Q

|

|

|

Load & Motor Drive |

||

Power MOSFET: MCAC130N04YHE3

|

Power MOSFET: MCACL320N04YQ

|

|

Interface |

||

TVS: SMF5.0AQ

|

TVS: SMF12AQ

|

|

EDS Protection: ESD1524D3BHE3A

|

EDS Protection:ESD24VD3BHE3

|

EDS Protection: ESDSB5VOD3BHE3

|

Lighting Control |

||

Power MOSFET: MCAC38N10YHE3

|

|

|

Body control modules play a vital role in vehicle safety, so their design should account for harsh conditions. MCC Semi has several discrete semiconductor solutions to maximize performance for your BCM designs.

Explore MCC’s diverse solutions for auto and EV applications, including:

On-board Charger (OBC)

EV Charging Station

Battery Management System (BMS)

DC-DC Converter

Advanced Driver Assistance System (ADAS)

Need assistance? Use the MCC website chatbot for fast, convenient support.

.png?width=50&height=50&name=mcc%20150x150%20(1).png)