Safety & Reliability Are Required

When it comes to designing automotive systems, safety and reliability are of utmost importance. This holds true for various components, including auto seat controls. These controls play a vital role in ensuring a comfortable and secure driving experience for both the driver and passengers.

Auto seat control functionality will vary based on the vehicle’s design. For most modern cars and trucks, standard seat control features include:

- Adjusting the driver and passenger seats forward and backward

- Configuring the angle of the seat for better visibility

- Positioning the headrest and back of the seat for support or comfort

- Ensuring seatbelts are properly fastened during operation

- Providing heating and cooling of the seats for maximum comfort

How do seat controls work?

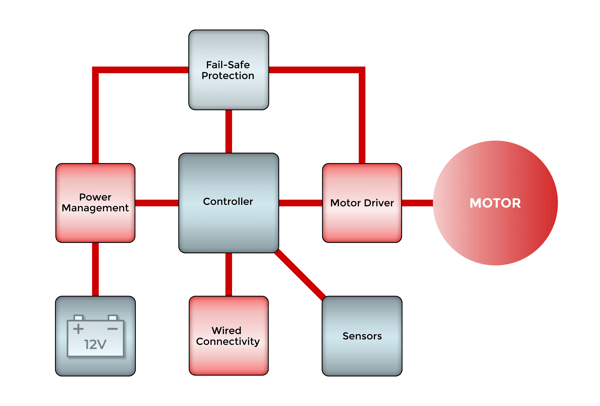

Powered by the vehicle’s battery, multiple built-in sensors provide inputs related to height, length, headrests, seat angles, and temperature of the seat’s components.

Switches allow the driver or passenger to adjust the seat as needed. They collect data points that are processed in the microcontroller, which directs the desired actions/reactions based on sensor input.

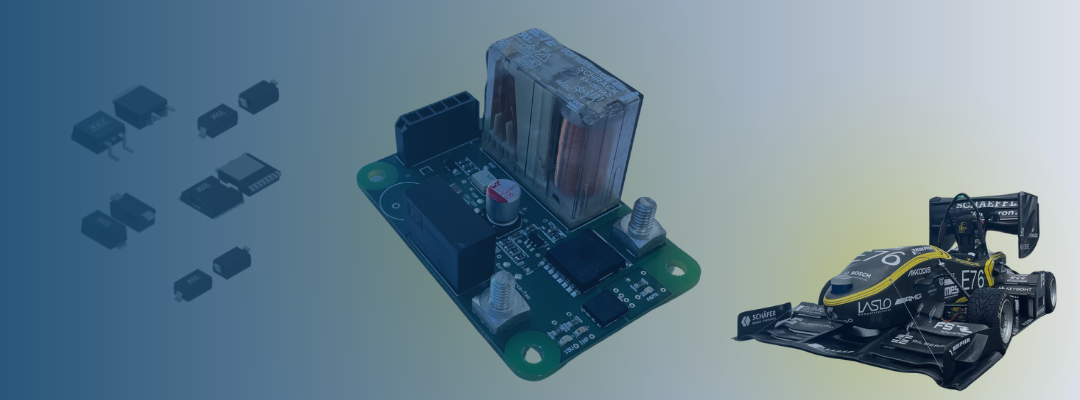

Brushless BLDC motors require fast switching to control speed and direction as the seats move. To reduce overall vehicle weight without sacrificing reliability, the BLDC motor has a high torque-to-weight ratio.

Fail-safe protection measures are included in the design to prevent overvoltage and ensure safety in worst-case conditions commonly found in automotive applications.

Design considerations

Engineers should weigh the following factors when specifying components for auto seat controls:

- Compact design - space is limited for the sensors and controls to perform all necessary seat functions

- Low on-resistance - must be used to reduce heat dissipation and avoid energy losses

- High-temperature capability - all components in the seat control must be able to withstand harsh environments and temperatures common in auto applications

- High current capability - the ability to perform reliably amid high current and fluctuating power is important in auto applications like seat controllers

- ESD/EMI protection - to prevent disruptions from electrostatic discharge or electromagnetic interference, appropriate protection devices must be in place

- Overvoltage protection - safeguarding CAN/LIN bus connectivity from transients and surges is essential for effective seat control design

- Efficiency - using as little power as possible is crucial to accommodate the many auto products that rely on the vehicle’s battery for power

- Applicable industry standards - the components used in seat controls are subject to stringent industry standards and requirements, including AEC-Q101 qualification

Auto Seat Control Block Diagram

Recommended Products

Power Management |

||

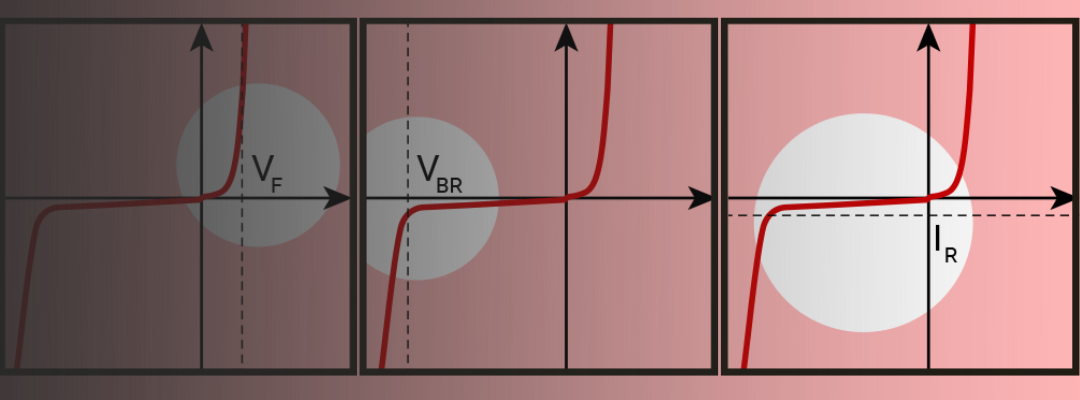

Schottky Barrier Rectifier: SS110Q-L

|

Schottky Barrier Rectifier: SK210Q-L

|

Schottky Barrier Rectifier: SK310Q

|

Battery Reverse Protection |

||

Power MOSFET: MCACL320N04YQ

|

Power MOSFET: MCG53N06AHE3

|

|

Motor Control |

||

MOSFET: MCACL320N04YQ

|

MOSFET: MCU75N06YHE3

|

|

CAN/LIN Bus Protection |

||

ESD Protection: ESD1524D3BHE3A

|

ESD Protection: ESD24VD3BHE3

|

|

Power seat controllers must be safe and reliable, even during harsh conditions. Choose the ideal components for your designs with MCC Semi.

Explore our robust portfolio designed for excellence in automotive design:

On-board Charger (OBC)

EV Charging Station

Battery Management System (BMS)

DC-DC Converter

Advanced Driver Assistance System (ADAS)

Have questions? Use the MCC website chatbot for convenient support.

.png?width=50&height=50&name=mcc%20150x150%20(1).png)