Preserve Signal Integrity Across Crucial Interfaces

As Ethernet continues to evolve from 100BASE-T1 to 10GbE and beyond, safeguarding high-speed data lines against electrostatic discharge (ESD) is more important than ever. From automotive networks to industrial infrastructure and consumer electronics, the reliability of Ethernet interfaces hinges on selecting the right ESD protection devices in the design stage.

At MCC, we provide state-of-the-art ESD protection solutions that go hand-in-hand with the evolution of Ethernet systems — ensuring signal integrity without having to compromise its compliance or performance.

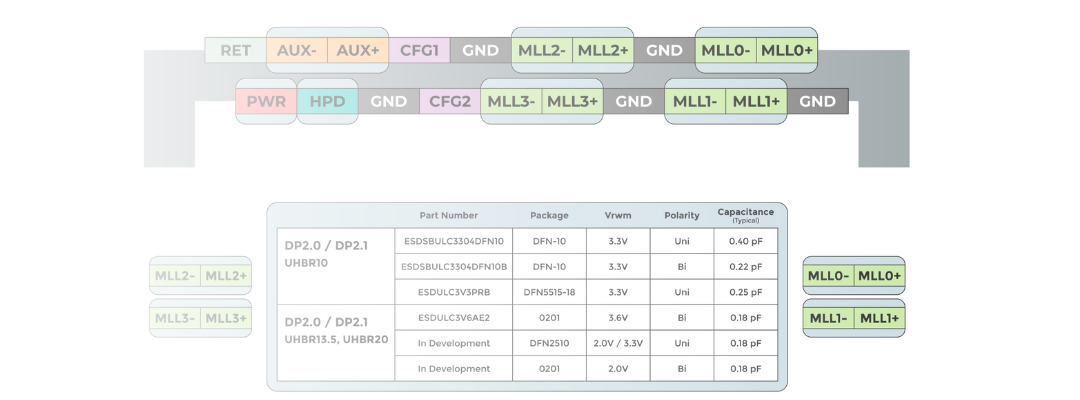

Automotive Ethernet (100BASE-T1 / 1000BASE-T1)

Automotive systems are highly vulnerable to electrostatic discharge (ESD) and electromagnetic interference (EMI). As Automotive Ethernet (including 100BASE-T1 and 1000BASE-T1) becomes more prevalent, compliance with rigorous industry standards — such as those from the OPEN Alliance — is imperative.

A typical Automotive Ethernet interface consists of key circuit blocks:

- Connector

- Common-mode choke or transformer

- Ethernet PHY

ESD can infiltrate through connectors or signal lines, endangering vulnerable downstream components. As such, ESD protection diodes are recommended to be placed as close as possible to the Ethernet PHY for better surge energy suppression after signal isolation.

MCC’s ultra-low capacitance solutions deliver robust ESD immunity while preserving signal quality for high-speed automotive communication.

Figure 1: Automotive Ethernet ESD Protection Schematic

%20(1).png?width=1110&height=463&name=Figure%201%20%20Automotive%20Ethernet%20ESD%20Protection%20Schematic%20MCC%20semi%20-%20micro%20commercial%20components%20(1200%20x%20500%20px)%20(1).png)

MCC’s Automotive Ethernet ESD Protection Solutions

|

Standard |

Part Number |

Package |

Breakdown Voltage VBR |

Reverse |

Capacitance (Typ.) |

|

100BASE-T1 |

SOT-23 |

100V |

24V |

2 pF |

|

|

1000BASE-T1 |

In Development |

DFN1110-3 (SWF) |

100V |

24V |

1 pF |

Note: Compliance with EMC requirements should follow official OPEN Alliance specifications. These solutions are optimized for board-level ESD protection while minimizing parasitic impact on differential signals.

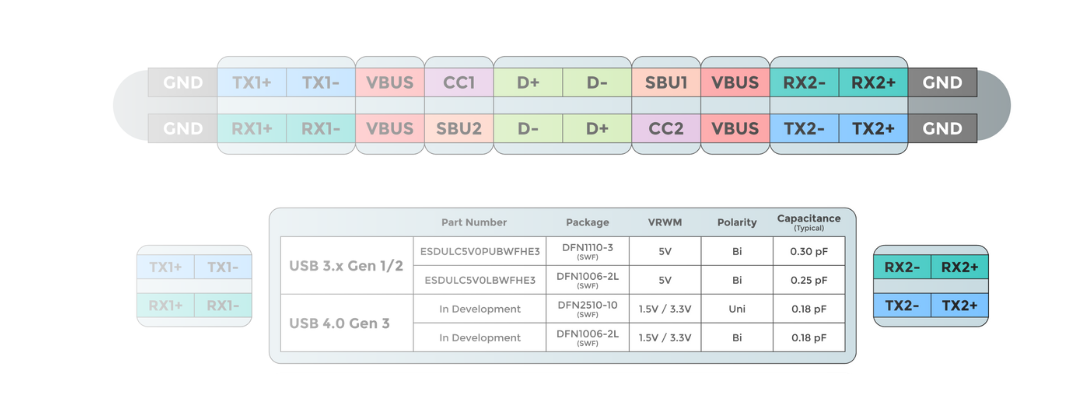

High-Speed Ethernet (1GbE to 10GbE)

As consumer and industrial Ethernet interfaces scale from 1Gbps to 10Gbps, ensuring signal integrity across PCB traces becomes increasingly challenging — especially when faced with ±30kV contact discharge or transient surge conditions.

At these speeds, even minimal parasitic capacitance can impair performance. With capacitance as low as 0.18pF, MCC's high-speed ESD protection devices meet demanding signal integrity requirements, making them particularly suitable for:

- Ethernet switches

- Routers

- NAS systems

- Industrial control devices

- Embedded applications

Figure 2: Ethernet Port Protection Zones

.png?width=1000&height=400&name=Ethernet%20PHY%20Port%20Protection%20Zones%20-%20mcc%20semi%20-%20micro%20commercial%20components%20figure%202%20%20(1000%20x%20500%20px).png)

|

Part Number |

Package |

Reverse Standoff Voltage VRWM(V) |

Polarity |

Capacitance (Typ.) |

|

DFN2510-10 |

5V |

Bi |

0.15 pF |

|

|

DFN-10 |

3.3V |

Bi |

0.22 pF |

|

|

DFN5515-18 |

3.3V |

Uni |

0.25 pF |

|

|

DFN-10 |

3.3V |

Uni |

0.40 pF |

|

|

In Development |

DFN2510 |

3.3V |

Uni |

0.18 pF |

Common protection strategies include:

- Line-to-Ground Protection: Dissipates surge energy to system ground in common-mode events.

- Line-to-Line Protection: Used in differential mode to clamp voltage across signal pairs.

- LED Control Signal Protection: Often overlooked, LED pins can be entry points for ESD during RJ45 contact.

Why ESD Protection Matters at the Design Stage

ESD and EOS (electrical overstress) events are a leading cause of Ethernet port failures — especially in exposed environments. These failures often originate at the connector, then propagate through transformers into the PHY layer.

Without proper secondary-side protection, the PHY is susceptible to performance degradation or permanent damage. MCC’s ESD portfolio ensures multi-layer protection that covers both differential and common-mode threats while maintaining compliance with IEC 61000-4-2 and IEC 61000-4-5 standards.

Systems designed without initial ESD protection for cost reasons are highly recommended to reserve PCB footprint space for protection devices. This mitigation strategy is crucial for maintaining upgrade paths to meet evolving protection standards or certification requirements.

Advanced Solutions for Now & What’s Next

Engineers designing vehicle networks or industrial edge systems can rely on MCC's ESD protection solutions to meet current Ethernet specifications while accommodating tomorrow's evolving standards.

Our upcoming ultra-low capacitance devices further reduce insertion loss, allowing for seamless integration in next-generation Ethernet architectures.

Ensure your Ethernet designs can withstand harmful electrostatic discharge with our robust ESD protection solutions.

Looking beyond Ethernet? MCC also delivers tailored ESD and surge protection for advanced USB-C systems — where fast response and ultra-low capacitance are key

.png?width=50&height=50&name=mcc%20150x150%20(1).png)