An Overview of EV Classifications, Connectors, and More

The popularity of electric vehicles may have gotten off to a slow start decades ago, but soon, EVs will be the global industry standard. Here’s why:

- The European Union mandated that all new cars, buses, and vans registered in Europe will be emission-free by 2035

- In Canada, recent legislation requires 100% of new vehicles sold in the country to be zero-emission vehicles (ZEV) by 2035

- In the U.S., there’s an executive order requiring 50% of all new vehicles sold to be zero-emission vehicles by 2030

To facilitate switching to e-powered options, electric means of transport must be safe, reliable, and affordable. But for plug-in hybrid vehicles (PHEVs) and battery electric vehicles (BEVs), powering up must also be convenient.

In this post, we’ll explain the classifications for EV charging methods, how they work, and which connectors are available.

How are EV charging stations classified?

Charging for electric and plug-in hybrid vehicles falls into three categories, each with pros and cons:

Level 1: Residential/Trickle Charging

Sometimes called the trickle effect, users can charge at home with a standard 120V/220V plug in their home or garage.

The convenience of plugging it in at home comes at a price — a short distance between charges. This means most EV owners who use Level 1 to charge must do it overnight. It’s a slow process. The recharge rate of 2 to 5 miles per hour of charge simply won’t get you very far, very fast. On the positive side, no additional equipment is needed in most cases.

Level 2: Commercial/AC Charging

Found in public charging stations and available for installation at home, these 240V outlets charge faster than the Level 1 option. However, several hours will need to be spent charging at a rate of approx 24 miles of range per hour.

For at-home and commercial uses, AC wall boxes are professionally installed for 3-4 times faster charging speeds compared to the trickle/Level 1 approach. For city dwellers and those without garages or driveways, Level 2 charging could be tricky and inconvenient to find the ideal spot to power up.

Level 3: Rapid or DC Fast Charging

DC chargers enable drivers to attain an 80% state of charge (SOC) in less than 30 minutes. Commonly used for public charging stations, DC fast-charging devices have power ranging from 50 kW to 150 kW, depending on the station’s set-up and the vehicle’s parameters and energy requirements. Of course, the time-saving method costs more, but is likely well worth it when you consider time spent charging with the other two options.

Quick charging requires high-current capacity, robust components, and adherence to strict safety standards in order to be safe and convenient for EV drivers.

EV Charging Classifications at a Glance*

| Level | Charger Location | Typical Use | Energy Supply Interface | Voltage Range | Power Level | Charging Period |

| Level 1: Residential | On-board, 1-phase | Home or office | Convenient, everyday outlet | 120V - 240V | Up to 2kW | 6 - 8 hours |

| Level 2: Commercial | On-board, 1- or 3-phase | Dedicated outlets | Dedicated outlet | 240V to 400V | 4 to 20 kW |

1 phase: 3 - 4 hours 3 phase: 1 - 2 hours |

| Level 3: Fast Chargers and Tesla Superchargers | Off-board, 3-phase | Commercial filling station/charging | Dedicated EVSE(adapter) | 480V to 600V or Direct DC | 50 to 100 kW | 20 to 30 minutes |

(*As of August 2023. Ranges, charging times, and technologies are evolving and will change over time.)

Let’s take a closer look at the topologies and connectors behind each of the three classifications.

EV Charging Power Topologies

The power topology of an electric vehicle charging station refers to how different loads are connected and configured to manage the electrical energy.

The right power topology depends on a variety of factors, including:

- Charging speed requirements

- Type of car being charged

- Type of charging station (indoor or outdoor)

- Local regulations

As EV charging continues to evolve, here’s a look at the methods used to power these emission-free vehicles:

On-Board vs. Off-Board EV Charging

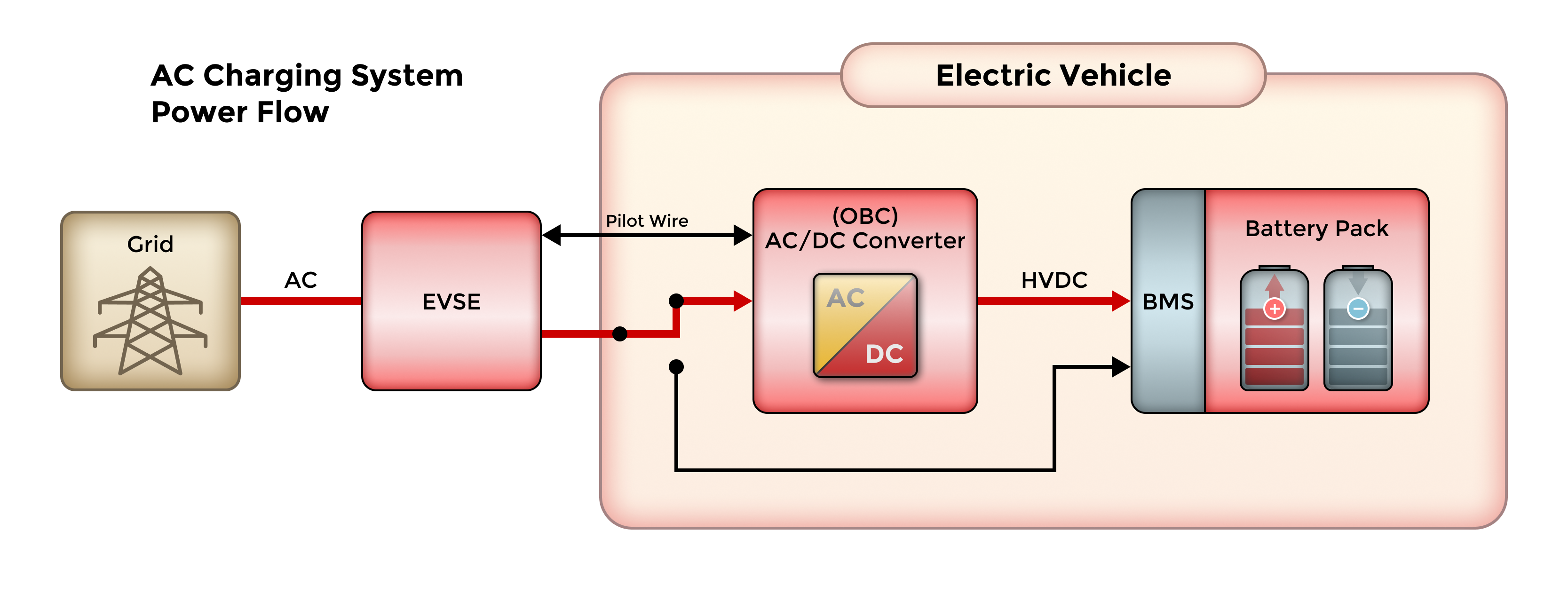

Because the vehicle’s battery only holds a DC charge, power conversion from AC to DC must take place. Where that conversion takes place determines whether the vehicle’s battery is charged on-board or off-board.

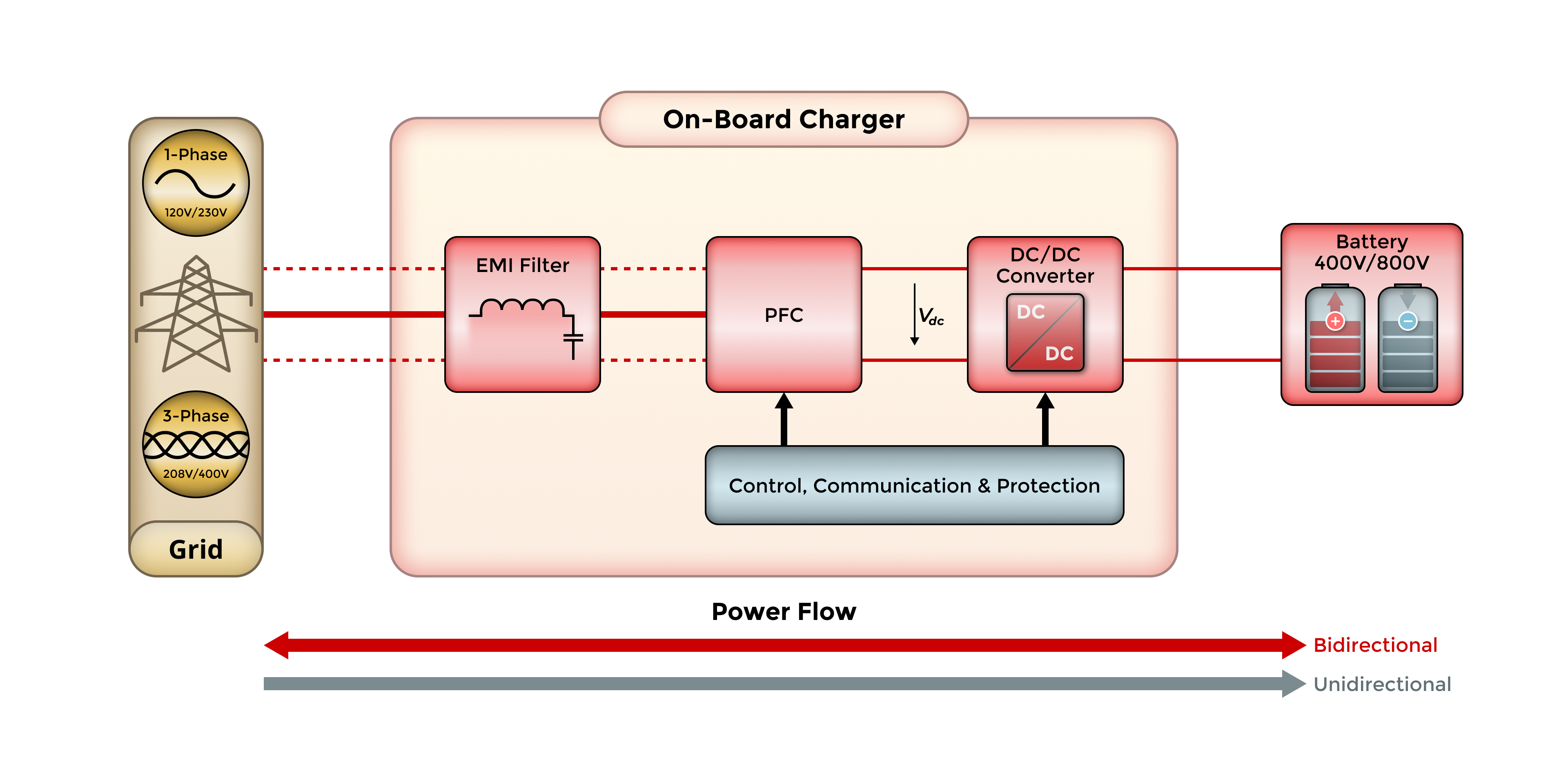

On-Board Charging

AC charging uses the vehicle's on-board charger (OBC) to convert AC power from the grid to DC power and charge the electric vehicle's battery. The OBC also regulates the DC voltage to support and protect the battery.

This conversion can occur via 1-phase or 3-phase power, with EMI filtering during the PFC (3-phase) configuration.

If a bidirectional flow is used, any excess energy can flow back to the grid.

OBC power ranges:

- Single phase input - from 1.5KW to 7.2KW

- 3-phase input - 11KW to 22KW

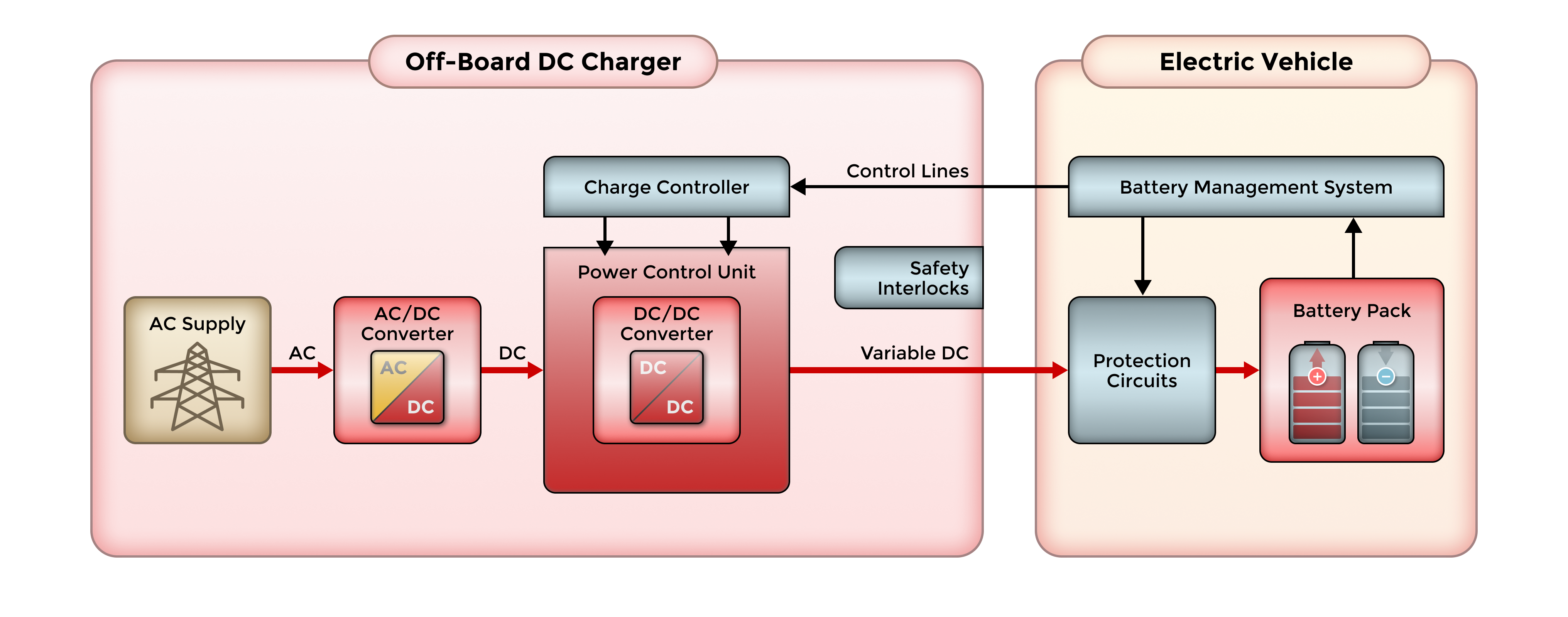

Off-Board Charging

For DC chargers, the conversion of AC to DC power must still take place — it just occurs inside the external DC charger itself rather than through the vehicle’s on-board charger.

The multi-step process looks like this:

AC to DC Stage

The AC/DC stage (also known as the PFC stage) is the first level of power conversion in an EV fast charging station. It converts the incoming AC power from the grid (380VAC to 415VAC) into a stable DC link voltage of around 800V, and EMI filtering suppresses unwanted noise/EMI.

DC to DC Stage

The DC/DC stage is the second level of power conversion in a DC charging station. It converts the incoming DC link voltage of 800V (in the case of 3-phase systems) to a lower DC voltage to charge the battery of an electric vehicle while bypassing the on-board charger and using a power control sub-unit converter. Delivering DC power directly to the EV enables significantly faster charging speed.

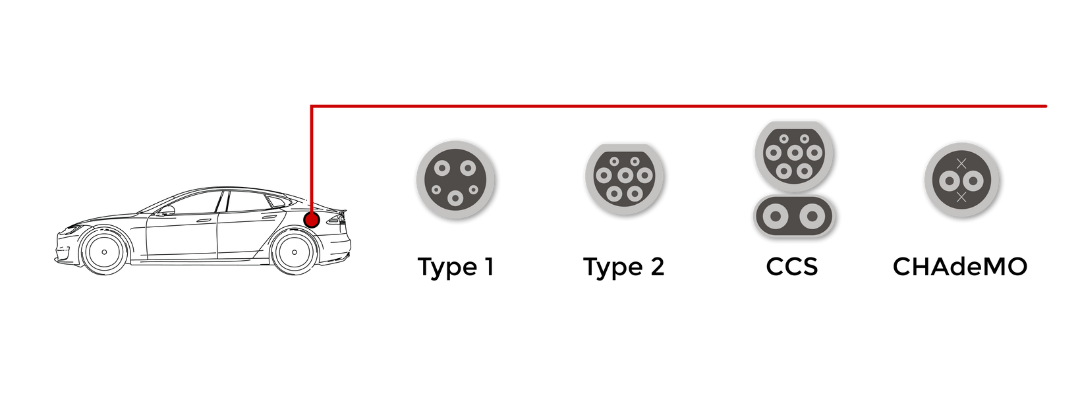

Understanding EV Charger Connector Types

Some industry standards were developed to support the compatibility and interoperability of charging systems while maintaining safety.

While there are a few additional options, there are two common standards for AC charging and two for DC charging:

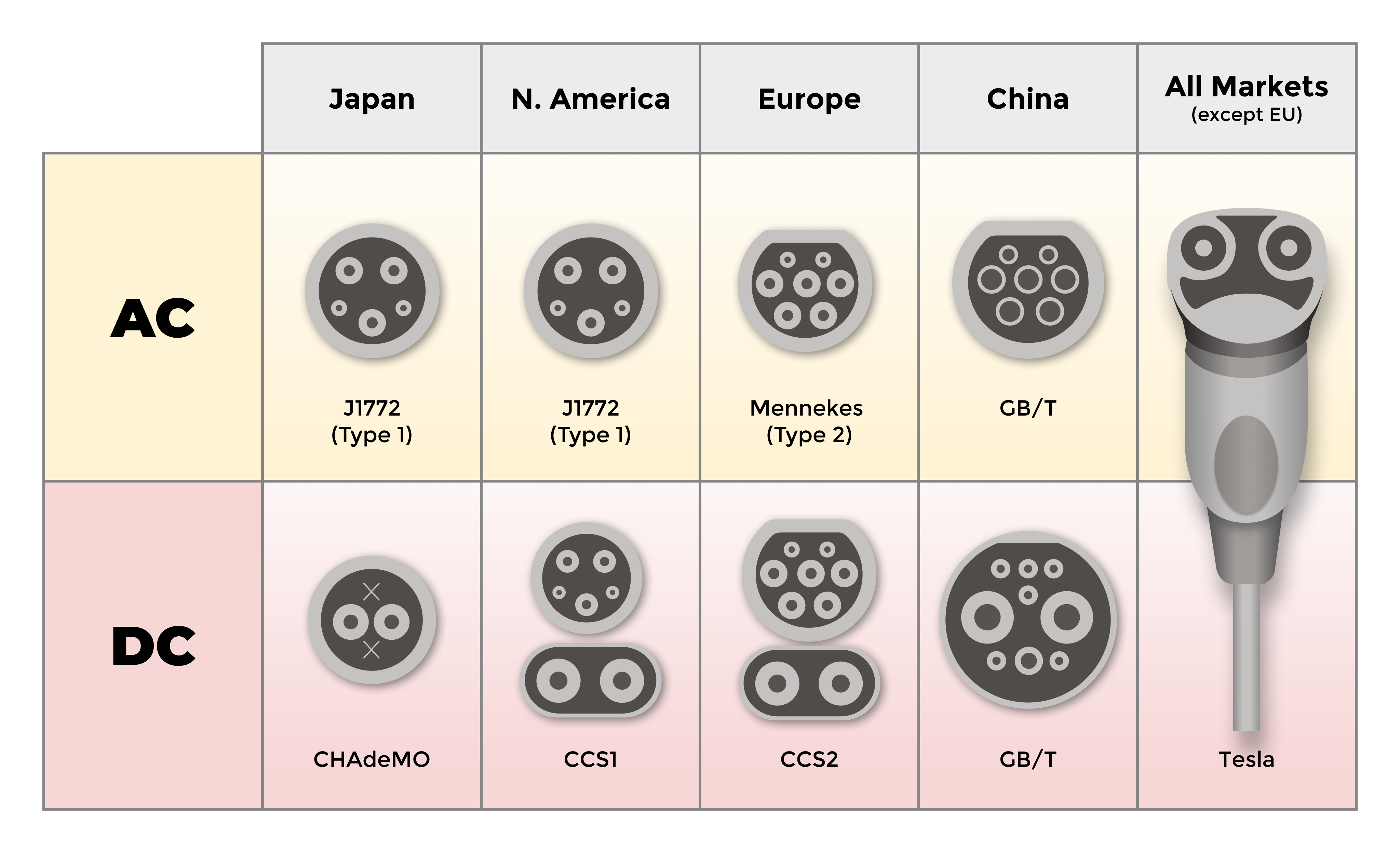

For AC (alternating current) charging from the grid or wall outlet:

Type 1

This single-phase plug is the industry standard for electric vehicles in America and Asia. Charging speed can reach up to 7.4 kW, depending on grid and car capacity.

Type 2

With three additional wires for faster current transfer, these plugs are triple-phase. At-home Type 2 connectors can charge up to 22 kW, and public charging stations with this type of plug can charge up to 43 kW, depending on grid and car capabilities.

Off-board DC Standards

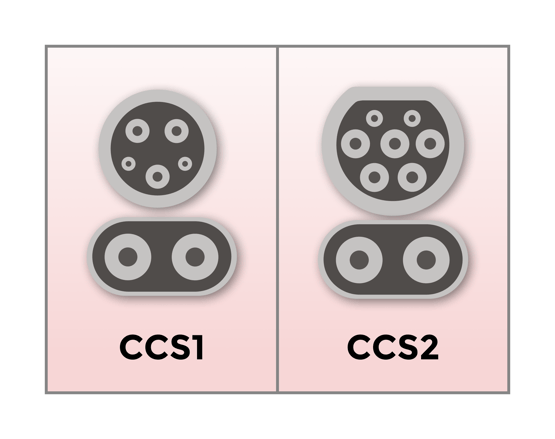

The two DC standards are the Combined Charging System (CCS) and the CHAdeMO standards.

- CHAdeMO - developed in Japan, the CHAdeMO standard allows for bidirectional charging and high charging capacities while ensuring accurate communication between car and charger. These can charge up to 100 kW and require an extra adapter to charge Type 1 and Type 2 systems.

- Combined Charging System - uses Combo 1 (CCS1) or Combo 2 (CCS2) connectors to power up to 350 kW, offering AC/DC charging from the same port. Two extra power contacts enable quick charging at a speed of up to 350 kW. These connectors are variations of the Type 1 and Type 2 connectors used in the AC options, with additional contacts for faster charging speed.

To make things more complicated, there are a few more charging options to consider:

Tesla’s Supercharger

Because there were no industry standards when Teslas were first developed, the automaker created its own proprietary plug. The Tesla Supercharger is capable of Level 1, 2, and 3 charging. Originally, only Tesla drivers could leverage this method at chargers in the Tesla Supercharger Network.

However, Tesla recently opened its private Supercharger Network to other electric car brands. Of course, non-Tesla drivers will need to use the Magic Dock adapter, which utilizes the CCS standard, to ensure compatibility with the Tesla charger.

At first glance, EV charging seems simple. However, in this ever-changing market, design engineers must carefully consider the requirements and standards for on-board and off-board charging options. MCC is here to help you specify the ideal component for the application and vehicle.

The Future: Smart DC Charging

As interest in EVs continues to grow worldwide, the methods for improving charge rates and technologies will evolve to meet the demand.

Vehicle-to-grid or V2G technology, opens a two-way energy transfer between the vehicle and the grid, where solar power can be used to power the EV, and any excess power stored in the EV can transfer power back to the power grid. While this method will dramatically reduce energy losses due to the thermal performance and eliminate strain on overworked power grids, the method will require large-scale adoption and efficient EV charging tailored to battery size. We foresee V2G gaining in popularity over the next several years.

In the meantime, fast DC charging is the ideal solution for busy consumers who require safety and speed — but it often comes at the expense of convenience because drivers typically have to find DC charging options away from home.

Be sure to check out MCC Semi’s comprehensive automotive solutions for EV charging and more:

On-board Charger (OBC)

EV Charging Station

Battery Management System (BMS)

DC-DC Converter

Advanced Driver Assistance System (ADAS)

Have questions or need assistance? Use the MCC website chatbot to contact us.

.png?width=50&height=50&name=mcc%20150x150%20(1).png)