Why Component Selection is Vital for Performance & Longevity

Battery management systems (BMS) are mission-critical devices for a wide range of power electronics applications — from renewable energy storage to portable devices. As the demand for reliable BMS solutions increases, so does the need for advanced MOSFET technology.

In this post, we’ll review Elektronika’s reference design for a 48V/80A BMS and how MCC’s forward-thinking MOSFET in the TOLL package can transform power flow management and system reliability.

Optimized Power Distribution: Elektronika’s Intelligent 48V/80A BMS Design

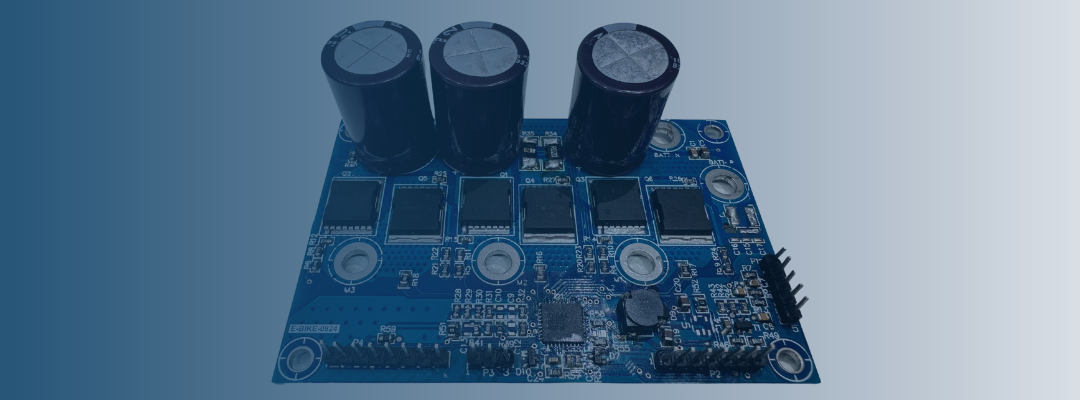

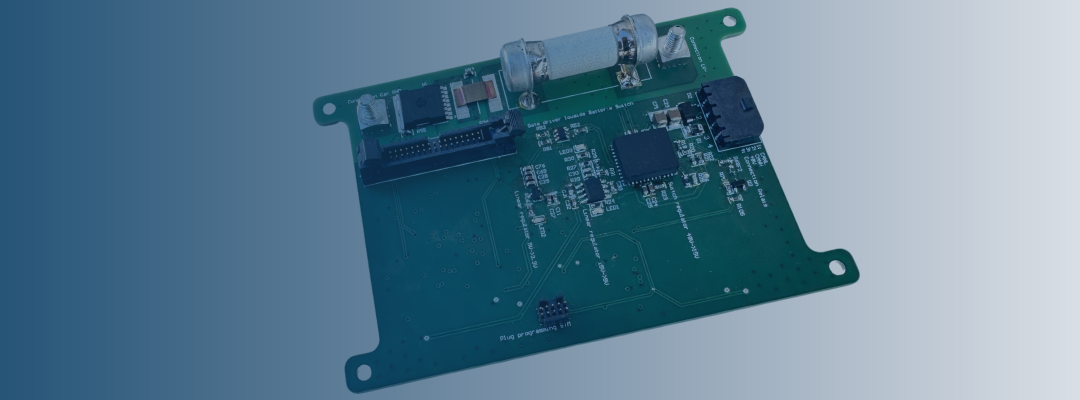

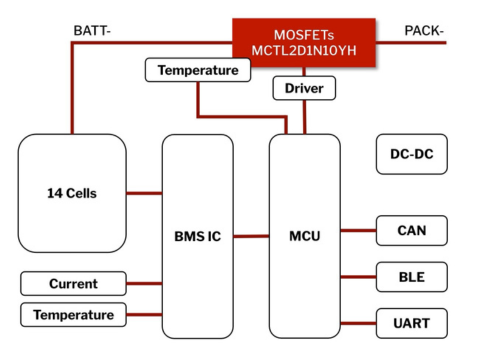

Elektronika’s reference board provides comprehensive monitoring, balancing, primary protection, and gauging functionalities for a 48V/80A battery management system supporting 7s to 14s lithium-ion or lithium iron phosphate battery configurations.

Designed for use in industrial applications, this board is capable of handling a maximum continuous discharge current of 80A and a peak discharge current of 100A for up to 30 seconds.

It supports a maximum continuous charging current of 50A with a charging voltage of 58.8V, utilizing both constant current (CC) and constant voltage (CV) charging modes.

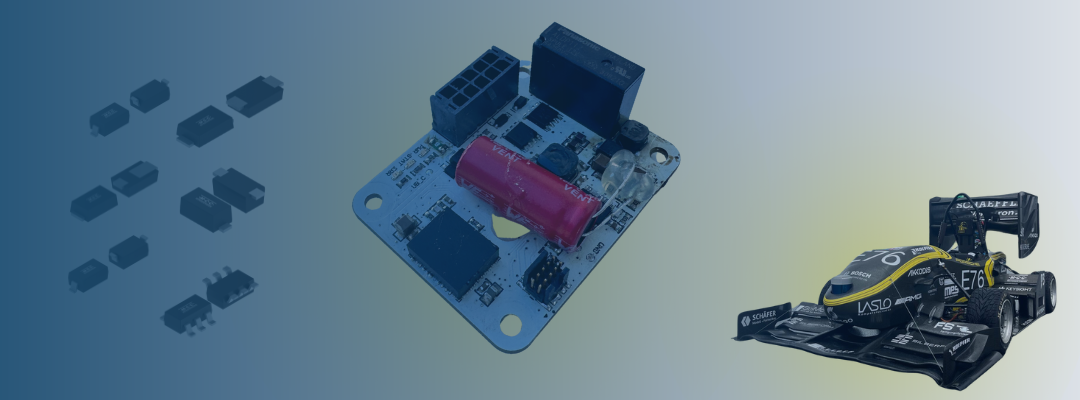

To maximize efficiency, Elektronika’s BMS board uses four pairs of MCC’s MCTL2D1N10YH TOLL-L8 MOSFETs as the charge and discharge FET. This advanced component significantly enhances battery management systems by ensuring proper power distribution and improved operation.

The MCTL2D1N10YH MOSFET delivers optimal efficiency and reliability with features like:

- Split-gate trench (SGT) technology for higher efficiency

- Low on-resistance for minimal power loss

- Low gate-drain charge for faster switching

- Operating junction temperatures up to 175°C for reliability

- Compact and powerful TOLL-8L package with high power density for design flexibility

The Role of a Battery Management System

A BMS performs several essential functions to maximize battery performance, longevity, and safety:

- Voltage Monitoring: Prevents overcharging or over-discharging by tracking the voltage of individual or groups of cells.

- Temperature Monitoring: Ensures that cells operate within safe temperature ranges to avoid overheating.

- Current Monitoring: Detects excessive charge or discharge currents, protecting the battery from potential damage.

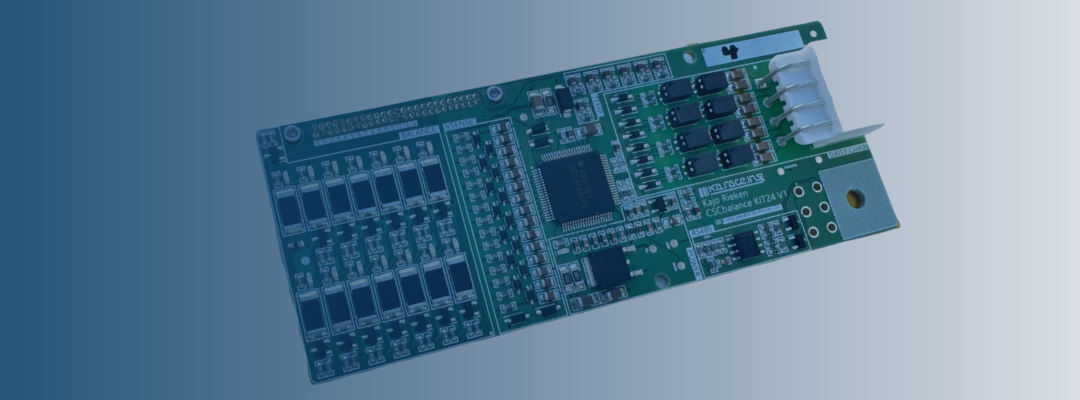

- Balancing: Equalizes the charge among cells to maximize capacity and extend lifespan.

- Communication: Interacts with other systems to report status and diagnostics, facilitating efficient operation.

Common BMS Design Challenges

Often operating in demanding work environments, engineers designing battery management systems face the following challenges.

- Overheating and Overcurrent: When a BMS doesn’t have ideal thermal performance and heat dissipation, it can lead to system damage and failure from overcurrent, overvoltage, or short-circuiting.

- Inefficient Power Management: Without proper power management, the BMS can perform poorly, causing power losses and diminishing overall system efficiency.

Fortunately, the MCTL2D1N10YH TOLL8 MOSFET is equipped with advanced features to effectively tackle these problems.

BMS Features to Consider

In addition to designing for the challenges associated with battery management systems, engineers should evaluate these factors:- Enhanced Reliability: Specify components engineered to minimize failure rates and maintain consistent and dependable operation even in harsh conditions.

- Efficient Power Distribution: Minimize power losses through highly efficient switching, which improves the overall performance of battery management systems while contributing to significant energy savings.

- Fast Switching Capabilities: Leverage a MOSFET with rapid on-and-off switching to provide precise control over current flow, crucial for battery protection and optimal charging/discharging cycles.

- Thermal Management: Implement proper heat dissipation components and strategies to prevent overheating, promoting stable operation under high-load conditions.

- Scalability and Flexibility: Design for versatile integration with components suitable for diverse applications in power electronics, including renewable energy, automotive, and portable electronics.

MOSFETs: The Critical Component in BMS Solutions

MOSFETs, or metal-oxide-semiconductor field-effect transistors, support a broad range of BMS functions, including:

- Switching and Control: MOSFETs act as switches to manage current flow into and out of the battery, protecting it from harmful conditions.

- Protection Circuits: These components quickly disconnect the battery in overcurrent or short-circuit situations to prevent damage.

- Cell Balancing: MOSFETs are used in active balancing circuits to redirect current from higher voltage cells to lower ones, ensuring uniform charge.

- Thermal Performance: Key to thermal management, MOSFETs help manage thermal dissipation by controlling power flow and reducing heat buildup.

These components are also vital for maintaining system integrity and performance in various challenging applications, including motor controls, power management, industrial automation, and HVAC equipment.

MOSFET selection significantly impacts safety, performance, and system lifespan when switching and controlling high-power circuits. MCC’s MCTL2D1N10YH MOSFET has the ideal combination of efficiency, thermal management, and power density to stand alone as an intelligent solution for industrial BMS design.

For a deeper dive into various MOSFET technologies and functions, check out our essential guide.

.png?width=50&height=50&name=mcc%20150x150%20(1).png)

.png?width=903&height=339&name=Elektronikas%20Advanced%2048V80A%20BMS%20Reference%20Design%20-%20mcc%20semi%20-%20power%20MOSFET%20-%20micro%20commercial%20components%20%20(800%20x%20300%20px).png)