How MCC Components Enable High-Reliability in High-Stakes Competition

In autonomous electric vehicle (EV) racing, split-second decisions can mean the difference between safety and disaster. That’s why the Emergency Brake System (EBS) is a mission-critical component of advanced self-driving vehicles.

In this post, we’ll cover the purpose, roles, and design challenges of the EBS, and take a closer look at KA-RaceIng’s innovative reference board powered by MCC components.

What is an Emergency Brake System?

An Emergency Brake System is an independent, automated braking circuit designed specifically for autonomous EV race cars.

If a hazardous condition is detected, the EBS doesn’t hesitate, bypassing manual controls to ensure the vehicle stops immediately.

Key Functions:

- Autonomous Activation: Triggers braking without human intervention if a fault or danger is detected.

- Safety Priority: Acts as a backup if primary systems fail or the vehicle loses control during autonomous operation.

- Pneumatic Pressure Monitoring: Continuously checks brake system pressure for reliability and responds accordingly.

The Role of Emergency Brake Systems in Autonomous Race Cars

In autonomous racing, there is no human driver onboard to react quickly in emergencies. The EBS is the vehicle’s last line of defense, ensuring the car can safely stop if any critical fault or erratic behavior occurs. There are several scenarios where EBS is essential:

- System malfunctions, including loss of communication and sensor failures

- Obstacle detection or track anomalies

- Failures detected by functional safety monitoring

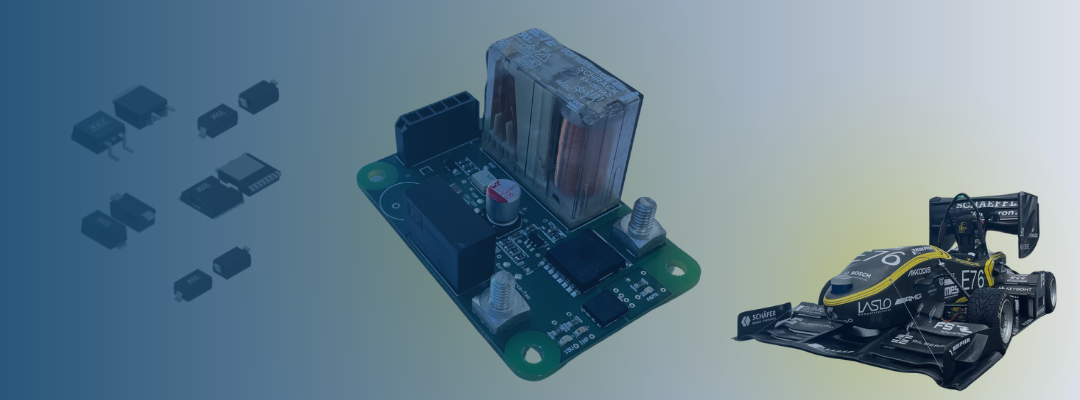

MCC Components Power Reliable EBS Performance

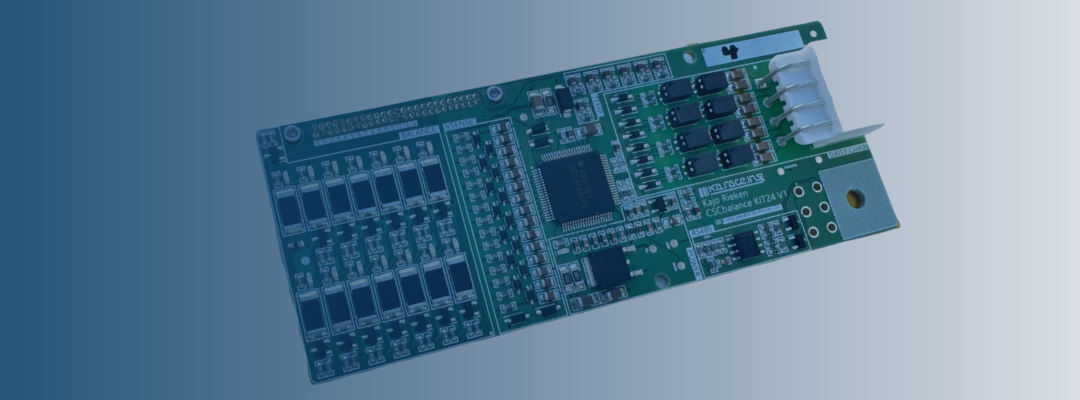

KA-RaceIng trusts its innovative KIT24 race car to deliver unquestionable quality should an emergency arise while the vehicle is in autonomous mode. Here are the advanced components we provided for maximum performance and reliability:

.png?width=800&height=400&name=Emergency%20Brake%20System%20(1).png)

Zener Diodes

- Part Number: MMSZ5225BHE3

- Specifications: Standard 3V, 500mW

- Application: IC input protection

- Part Number: BZT52C3V0HE3

- Specifications: Standard 3V, 500mW

- Application: IC input protection

- Part Number: MMSZ5248BHE3

- Specifications: Standard 18V, 500mW

- Application: Protect board from overvoltages

Small Signal Schottky Diodes

- Part Number: SMD18PLHE3

- Specifications: 80V, 1A

- Application: Freewheeling diode for relay

TVS Diodes

- Part Number: SMA6J48AFLQ

- Specifications: 600W, 48V

- Application: Protect IC input from transient overvoltage

Standard Recovery Rectifiers

- Part Number: GS1JPBQ

- Specifications: 600V, 1A

- Application: Surviving inrush currents and voltage surges

Small Signal MOSFETs

- Part Number: SIL04P06YHE3

- Specifications: -60V P-Channel MOSFET in low-impedance SOT23-6L package

- Application: Actuator control switch

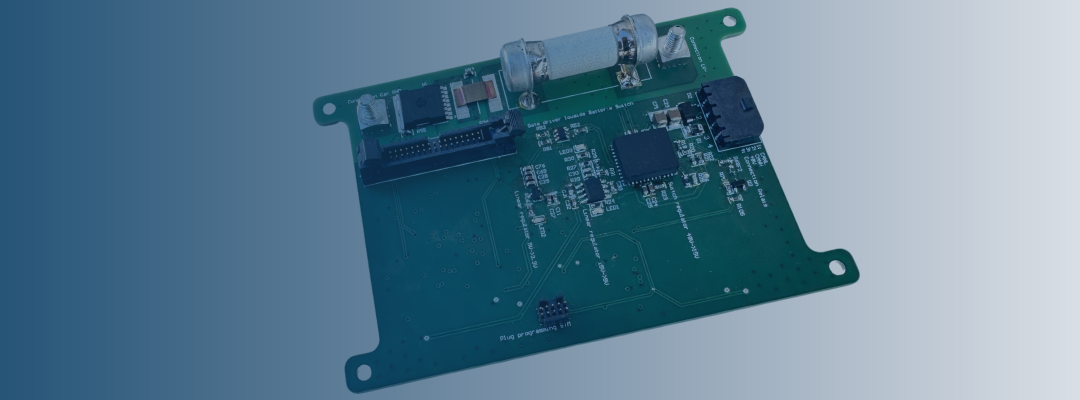

Emergency Brake System Design Challenges

Designing an EBS for autonomous EV race cars requires balancing compactness, durability, and safety with a variety of technical and environmental challenges. Every component and subsystem must perform flawlessly under extreme conditions to ensure the brakes activate immediately and reliably when needed.

Some of the most common challenges engineers face when developing EBS solutions tailored to the demands of high-performance autonomous racing include:

- Compact & Clear Integration: Packing all safety-critical functions onto a small PCB located near other electronics and actuators without causing overheating or signal interference.

- Robust Component Selection: Choosing components designed to reliably handle voltage surges, inrush currents, and transient spikes under harsh conditions.

- Functional Safety Compliance: Meeting strict automotive safety standards (such as ISO 26262) through redundancy, fail-safe mechanisms, and rigorous fault detection to avoid any single point of failure.

- Reliable Pressure Monitoring: Continuously tracking pneumatic or hydraulic brake pressure to detect sensor or wiring faults instantly, avoiding unnoticed loss of braking capability.

- Low-Latency Response: Ensuring the system detects hazards and actuates the brakes within milliseconds by minimizing propagation delays from input detection to actuation.

- Isolation from Main Systems: Electrically and logically isolating the emergency brake path from the standard brake system so that a failure in the primary system does not affect emergency operation.

- Environmental Robustness: Designing the board and components to withstand vibration, heat, dust, and moisture typical of race car environments without compromising performance.

- Testing and Diagnostics: Providing full testing and diagnostic capabilities to proactively detect latent faults or failure warning signs.

Addressing these challenges is crucial to delivering a safe, reliable, and race-ready Emergency Brake System for challenging autonomous vehicle applications.

Brake vs. Emergency Brake System: Understanding the Difference

Autonomous vehicles need both standard and emergency brake systems, yet they differ in many ways:

|

Standard Brake System |

Emergency Brake System (EBS) |

|

Used during normal driving/braking |

Only activated in emergencies or faults |

|

Controlled by driver or primary ECU |

Operates autonomously based on safety logic |

|

Designed for repeated use |

Designed for immediate action and high reliability in rare scenarios |

|

Integrated with main vehicle controls |

Operates via an isolated path to minimize risk of shared failure |

Why the EBS is Critical to Autonomous EV Racing

The EBS is more than a backup braking system — it safeguards the vehicle and its surroundings when racing without a human in the driver’s seat.

MCC components deliver the robust protection, compact design, and strict safety compliance required for reliable EBS performance, whether on the track or off.

As autonomous EV racing advances, so will the need for safe and sophisticated emergency braking systems and other components.

Discover all of KA-RaceIng’s innovative reference boards powered by MCC solutions.

.png?width=500&height=300&name=KA-racing%20-%20MCC%20sponsor%20-%20electronica%202025%20-%20mcc%20-%20micro%20commercial%20components%20%20(600%20x%20300%20px).png) |

.png?width=500&height=300&name=KA%20Racing%20Team%20-%20Sponsor%20MCC%20semi%20-%20Micro%20Commercial%20Components%20500x300%20(7).png) |

|

|

.png?width=50&height=50&name=mcc%20150x150%20(1).png)