MCC’s Advanced Battery Technology Solutions Fuel KA-RaceIng

On the race track, cell supervisory circuits are integral to ensuring speed and safety, safeguarding electric race cars from potential failures.

In this post, we’ll cover important functions of the cell supervisory circuit and showcase the reference board KA-RaceIng used in the KIT24 car. We’ll also share challenges engineers may face when designing this key component.

What is a Cell Supervisory Circuit (CSC)?

An essential component of a battery management system (BMS) used in electric and hybrid vehicles, the cell supervisory circuit has big responsibilities, including managing individual battery cells in a high-voltage battery stack. By monitoring cell voltage, temperature, and sometimes current, the CSC ensures safe and efficient operation of the battery pack.

Working as an intermediary system, the CSC gathers data from each battery cell and forwards it to the master BMS controller. This data enables the BMS to perform critical functions, such as cell balancing, fault detection, and protection against overcharging or over-discharging. These features are indispensable for maintaining battery health, prolonging battery lifespan, and ensuring the safety of EVs during operation.

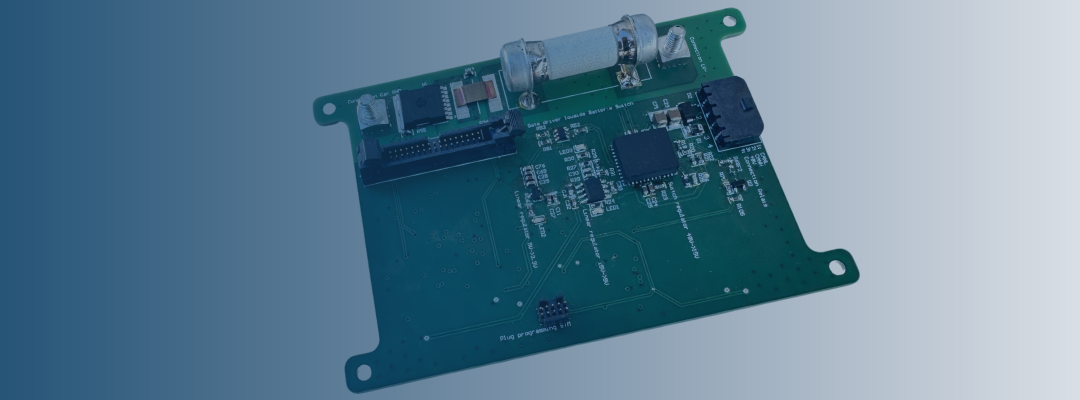

The Role of the Cell Supervisory Circuit in the KIT24

In KA-RaceIng’s KIT24 electric race car, the cell supervisory circuit operates as a secondary component, or subset within the BMS architecture. Its primary functions in supporting the BMS include:

- Connection to High-Voltage Battery Stacks: Establishing a communication link between the battery stacks and the high-voltage BMS. This connection facilitates real-time monitoring and control of individual cells.

- Signal Conversion: Transforming raw data on metrics such as voltage and temperature into communication signals that can be interpreted by the BMS, enabling accurate monitoring of battery conditions.

- Cell Balancing: Equalizing the charge across all cells in the battery pack. Balanced cells improve energy efficiency and prevent overheating or damage caused by uneven charging.

The CSC’s functions are vital for enabling KIT24 to perform optimally under competitive conditions, where precision and reliability make all the difference.

MCC Enhances CSC Performance

MCC provides industry-leading solutions for KA-RaceIng’s CSC design that deliver robust and reliable performance, even in demanding motorsports scenarios.

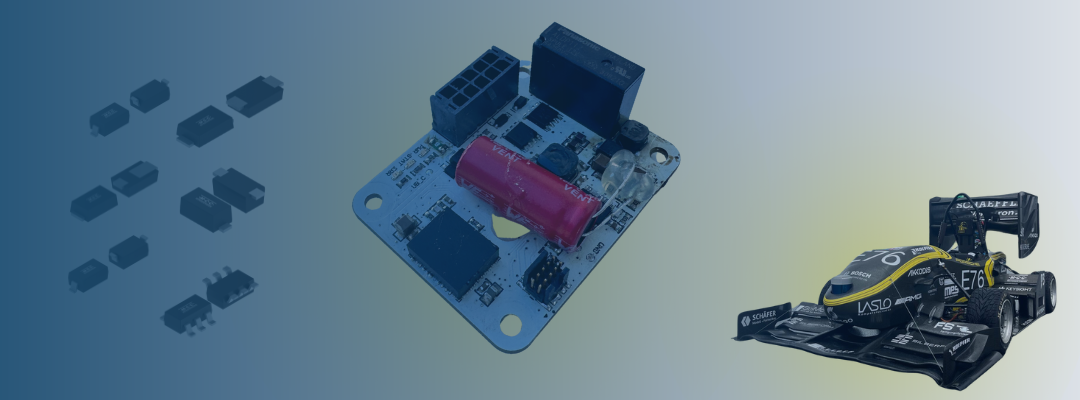

We equipped the KIT24 car with these semiconductor products:

Zener Diodes

- Part Number: BZT52B6V2JSHE3

- Specifications: 200mW, 6V Zener diodes

- Application: Voltage regulation to ensure stable operation during fluctuating power demands.

TVS Diodes

- Part Number: SMA6J54AQ

- Specifications: 600W, 54V TVS diodes

- Application: Overvoltage protection for the BMS IC, especially during hotplugging scenarios where transient spikes can occur.

Common Design Challenges in Cell Supervisory Circuits

Designing an effective cell supervisory circuit comes with its own set of challenges for engineers:

- Accuracy in Measurement: Precise monitoring of cell voltage and temperature is critical, as slight inaccuracies can lead to unsafe operating conditions or reduced battery performance.

- Overvoltage Protection: High-voltage systems are prone to transient spikes, especially during hotplugging or sudden load changes. Implementing reliable overvoltage protection is crucial to prevent damage to sensitive components.

- Cell Balancing Algorithms: Developing algorithms that efficiently balance cell charge without introducing excessive heat or energy loss is a complex, yet crucial task for ideal performance.

- Environmental Robustness: Cell supervisory circuits must be designed to endure extreme temperatures, vibrations, and electromagnetic interference (EMI) found in automotive applications.

- Safety Standards Compliance: Meeting strict industry safety regulations when applicable adds complexity to CSC design and validation processes.

MCC’s products address these challenges by offering high-quality components that enhance reliability, precision, and durability in CSC designs.

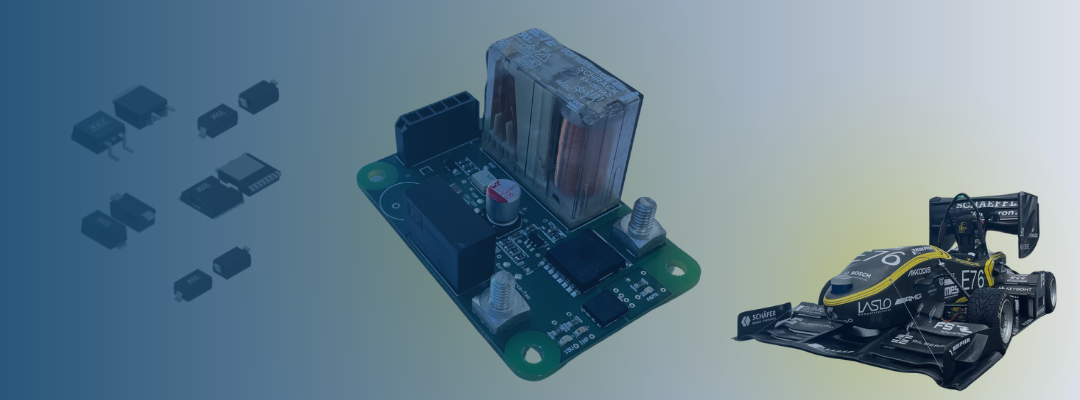

KA-RaceIng: Engineering Excellence in Motorsports

We’re a proud supplier and sponsor of KA-RaceIng, an exceptional Formula Student team from the Karlsruhe Institute of Technology (KIT). KA-RaceIng represents the pinnacle of student innovation, excelling in the design, manufacturing, and racing of “formula style” (open-wheel, single-seat) electric cars competing internationally in Formula Student, the world’s largest engineering competition for students.

Explore all of the advanced MCC components KA-RaceIng utilized in the KIT24 car.

.png?width=500&height=300&name=KA-racing%20-%20MCC%20sponsor%20-%20electronica%202025%20-%20mcc%20-%20micro%20commercial%20components%20%20(600%20x%20300%20px).png) |

.png?width=500&height=300&name=KA%20Racing%20Team%20-%20Sponsor%20MCC%20semi%20-%20Micro%20Commercial%20Components%20500x300%20(7).png) |

|

|

.png?width=50&height=50&name=mcc%20150x150%20(1).png)