How Increasing Demand is Evolving ESS Product Design

To combat climate change, many governments are aiming to reach zero emissions by 2050. Their efforts require a multi-pronged approach that puts energy storage systems in the driver’s seat.This demand is driven by many factors, including:

- Batteries for electric vehicles

- Peak power needs

- Existing grid infrastructure requirements

- Growing global population

All these factors mean the energy storage market is expanding at a compound annual growth rate (CAGR) of 17% and is set to reach $20 billion in 2023.

Energy storage applications

Energy storage systems are a vital part of a more sustainable energy future. All components must work seamlessly to collect, store, and distribute energy when and where needed. Common ESS applications include:- Battery management systems

- Inverters

- Meters

- Electric panels

- On-board chargers

- Off-board chargers

The devices that field these technologies must keep pace with existing needs while continuously evolving.

Trends in the ESS market

Energy storage systems are the glue that enables us to collect, store, and distribute reliable green energy amid increasing demand.

Renewable energy sources that produce intermittent power — wind and solar — will require a power grid that is more flexible and resilient.

Since lithium-ion batteries are an efficient and reliable source of stored energy, the World Economic Forum predicts global demand for them will reach 221 gigawatt-hours in 2030.

Together, these two global trends of e-mobility and renewable energy are driving big changes in ESS design, including:

Increased power density

In EVs, space is limited, so increasing battery size isn’t feasible. This means designers must find creative ways to increase efficiency and thermal performance while improving power density. Silicon Carbide components are often used for high-voltage, high-frequency applications.

Off the road, the portable solar devices with battery systems and an electrical outlet widely used in countries where reliable power is not readily available, there’s a shift from 48V to 400V battery technologies.

Thermal management and high-frequency conversion

Thermal management is also a key consideration, as wide bandgap (WBG) technologies allow for high-frequency conversion, which is essential for increasing power densities to meet market needs.

Focus on power management

Improving power density, reducing electromagnetic interference, maintaining signal integrity, and preserving power, are all needed to keep pace with consumer demand.

ESS design considerations

Many factors that go into the safe, reliable operation of energy storage systems. OEMs and engineers must carefully balance costs with energy density, power density, and the cycle life of the device.

- Safety - for ESS design, safety is Job 1. Systems must be designed to withstand extreme conditions, temperatures, shocks, and vibrations.

- Cycle life - the number of times an ESS can be charged and discharged in its lifetime is a major design factor for ESS that need to be operated for a long period of time, such as those used in grid-scale energy storage systems.

- Energy density - how much energy can be stored by unit volume is paramount for ESS that need to be lightweight and compact, like those in electric vehicles.

- Power density - the amount of power delivered per volume for ESS that need to provide a high discharge rate. For large, grid-scale systems, power density is essential.

- Energy efficiency - how much of the stored energy is actually available for use? The materials used in the components can impact efficiency levels.

- High-power handling - the ability to handle large power loads is required for grid applications and will be increasingly important as battery life is extended in EVs.

- Power conversion - how efficiently can the device transition from stored to delivered power?

- Fast switching speed - switching between two states quickly is essential for devices that must respond promptly to changes in power demands.

- Reliability - when it comes to energy, the device needs to perform without failure. Especially in backup power applications when the grid has gone down.

- High-temperature capability - effective thermal modeling and heat dissipation can increase temperature capability, which is invaluable in high-current applications, or those where operating temperatures also run high (like sun and wind farms in desert environments).

- High current handling - the ability to handle large currents is critical for large-scale grid operations that handle various changes in demand.

- Low on-resistance - reducing the amount of energy loss during operation is crucial, and low on-resistance contributes to a more efficient design.

- Low reverse recovery time - recovering from a reverse current quickly reduces energy losses when the system is in use, which contributes to overall efficiency,

- AEC-Q compliance - EV on-board chargers must meet these stringent requirements.

Energy Storage Applications in Action

Let’s take a closer look at some common ESS applications and the components that drive them:

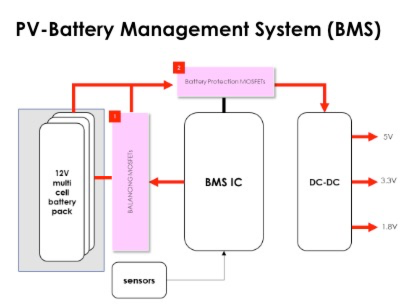

Photovoltaic Battery Management System

For renewables, several 12V batteries are connected and require MOSFETs for balancing and battery protection before safely distributing the power via a DC-DC converter.

Recommended products:

| 1. Balancing | 2. Battery Protection |

| N-Channel MOSFET | N-Channel MOSFET |

| 40V VDS | 40V to 100V |

| DFN5060 package | DFN5060 package |

| View Product Details | View Product Details |

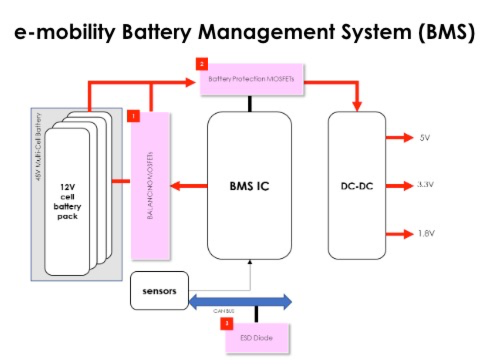

Electric Vehicle Battery Management System

For EV battery systems, a multi-cell 12V battery pack requires MOSFETs for balancing and battery protection as it distributes the energy via DC-DC converter. An ESD diode helps protect the device from interference and transients for the communication lines.

Recommended products:

| 1. Balancing | 2. Battery Reverse Protection | 3. CAN BUS |

| N-Channel MOSFET | N-Channel MOSFET | ESD |

| 40V VDS | 40V to 100V | SOD-323 |

| DFN5060 package | DFN5060 package | SOT-23 |

| View Product Details | View Product Details | View Product Details |

Renewable Energy System

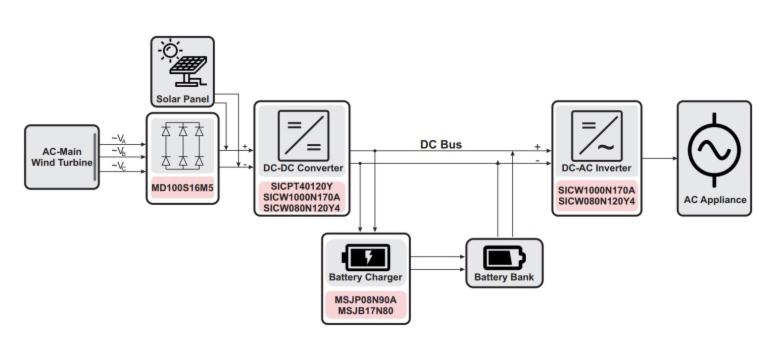

In this example, several semiconductors must work together to move solar or wind energy to the DC-DC converter, then distribute it to the battery charger where it can be used later via a DC-AC inverter.

Recommended products:

| Standard Recovery Power Module | SiC SBD | SiC MOSFETs | Power MOSFETs |

| Three-phase bridge rectifier | High-temperature capability | High-temperature capability | N-channel super-junction |

| Converts AC to DC | Fast switching speed | High current handling | High voltage handling |

| Maximum voltage rating | Low forward voltage drop | Low on-resistance | High current capacity |

| Chassis mount design | Low reverse recovery time | Fast switching speed | High power dissipation |

| SICW1000N170A | MSJP08N90A | ||

| MD100S16M5 | SICPT40120Y | SICW080N120Y4 | MSJB17N80 |

As the world moves toward more environmentally friendly energy consumption, ESS will need to evolve to accommodate increasing demands and power requirements.

MCC is your partner for sustainable solutions to harness, store, and distribute energy in ways that are safe, cost-effective, and efficient.

Learn more about MCC’s innovative ESS solutions in this flyer. Need assistance? Use the MCC website chatbot to contact us.

.png?width=50&height=50&name=mcc%20150x150%20(1).png)