Strategies for Minimizing Costly Delays

While no one can predict a supply chain disruption, the Covid pandemic taught several painful lessons for manufacturers, OEMs, and suppliers up and down the supply chain.

Any supply setback is more than an inconvenience — it is often accompanied by hefty consequences. Here are some surprising statistics on just how costly delays can be:

Only 45% of semiconductor NPIs launch on time. Less than half of semiconductor product launches meet their original launch date. And the longer the product holdups, the more harm is done to the bottom line.

When a semiconductor misses its time-to-market window by three months, revenues shrink by 27%. Yes, you read that correctly. And according to DevOps solutions provider Perforce, a six-month lag can lead to a reduction in revenue of 47%!

Over 40% of semiconductor development projects exceed the planned budget. These overages can be caused by a host of factors, including lead times and time spent finding a new supplier if there’s a supply issue.

What happens to your bottom line if your product launch is stalled on the front end and reduces profitability by being way over budget once the launch finally takes place? That’s a recipe for failure in today’s competitive marketplace.

There are some steps engineers and procurement teams can take now to help minimize delays and their negative outcomes.

Work with proactive manufacturers that control what they can

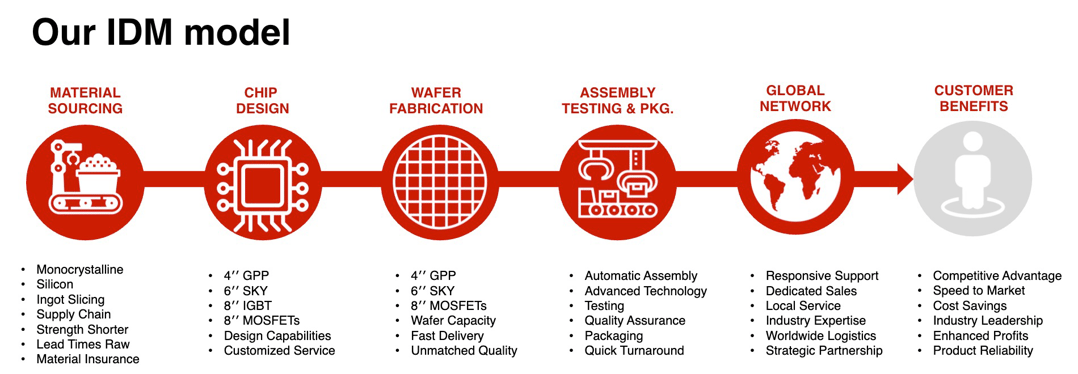

At MCC, our integrated device manufacturer (IDM) model helps us maintain greater control over the supply chain.

By owning crucial links in our supply chain — from materials to manufacturing and distribution — our team can anticipate needs and scale up or down, while ensuring we have enough materials to meet market demands.

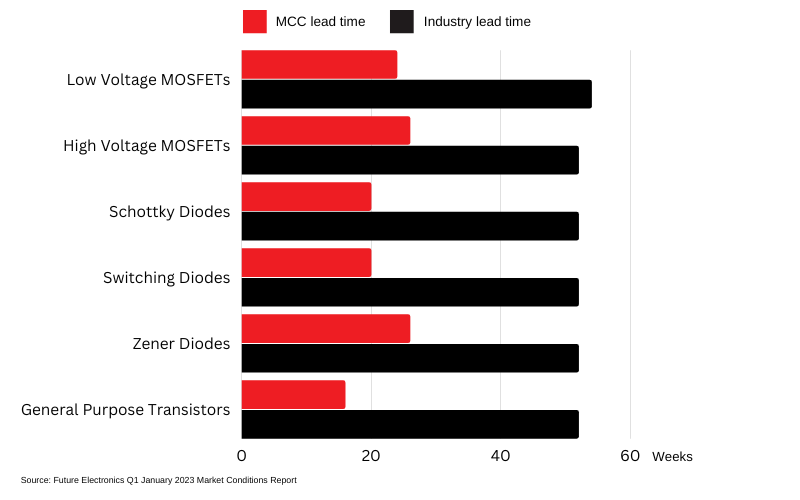

Our IDM model has served us — and our customers — well. According to Future Electronics’ Q1 2023 Market Conditions Report, MCC had average lead times nearly half that of the industry in key categories:

“When I think of MCC, I think of speed. MCC offers fast responses to customer needs, quick resolution to challenging supply issues, and world-class lead times for high-quality, cost-competitive products.”

- Global Commodity Manager, Leading Electronics Manufacturer

Qualify more than one Tier 1 supplier

Even if you have a Tier 2 in place, it’s advisable to create an approved vendor list (AVL) so you can be ready to react if one supplier in your supply chain has an issue. Being able to hit the ground running with other vendors you’ve already qualified and have relationships with can help stay a few steps ahead of the competition.

Other benefits of an approved vendor list include:- Reduced lead times

- Streamlined procurement

- Quality control

- Potential cost savings

- Minimal production delays

Specify parts you’ve used in other components

In some cases, reusing a previously specified part in a new product can save up to $20,000 or more when you factor in the time to specify, source, and qualify a new one. If there’s a breakdown in communication or the engineering team can’t quickly find part information, they may specify a new design, which can cause other problems. Research by Tech-Clarity found that 1/3 of the non-value-added time engineers waste sourcing parts is spent working with outdated information.

In one anecdotal example from Electronic Design, an engineer spent about an hour trying to find the right part to reuse, then got frustrated and specified a new one. From there, the part had to be sourced, qualified, and ordered, adding more time (and costs) to design and production. Reusing what already worked (as long as it's in stock) can help you shorten design, procurement, and production time. But engineers must have access to this information.

Design for availability

When planning the NPI roadmap and prioritizing which new products to design first, make sure procurement teams and engineers have conversations about which components are readily available. Then design for availability, making design modifications (and likely compromises) to design for those parts.

Of course, this won’t always be a viable solution. But open communication and sharing up-to-date information can help inform design decisions where a small tweak to a power rating or a package size could lead to ample component supply and crosses, just in case. These decisions will need to be made by stakeholders from various departments.

Get professional help

Collaborate with authorized distributors, or go directly to the component manufacturer to discuss your needs and priorities. These experts will have high visibility into what is happening within your market and the semiconductor industry and can help you pivot to minimize delays in your product design and production.

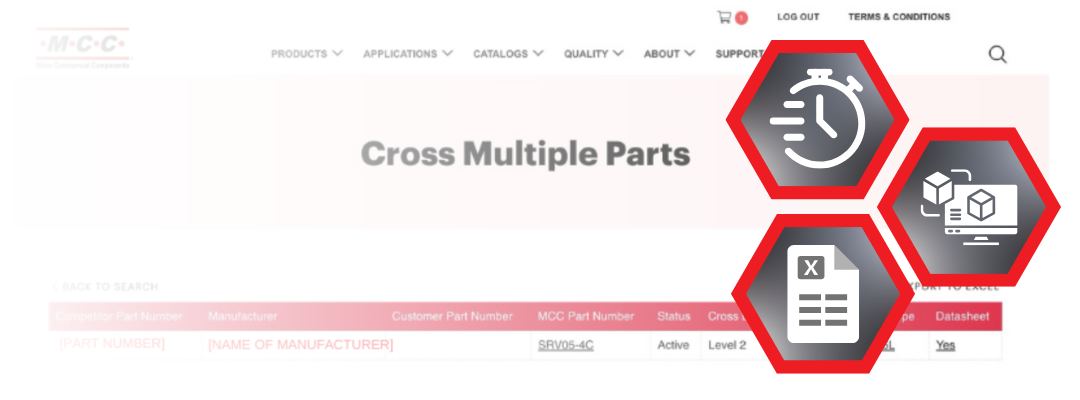

Want to find a replacement to shorten your lead time on a product? MCC has a global team ready to conduct crosses and find drop-in replacements for you. We also have robust search tools and features on our website to help you source a replacement, compare lead times, and order the right component for your needs.

Have questions or need assistance? Use the MCC website chatbot.

.png?width=50&height=50&name=mcc%20150x150%20(1).png)