Why You Need One & How to Get Started

Using single-source electronics components has never been a riskier endeavor. According to the Harvard Business Review, there have been seven semiconductor crises over the last 28 years (including the one we are currently experiencing). These delays can be caused by a small, isolated issue at a certain facility, geopolitical or weather conditions in a region, a global bottleneck like the Covid pandemic, or anything in between.

The good news is there are steps engineers and manufacturers can take now to help minimize costly delays in product design and production when one component becomes unavailable.

Engineers and manufacturers should consider prioritizing their approved vendor list (AVL) — or creating one if they don’t have one in place.

What’s an approved vendor list?

An approved vendor list, or AVL, is a tool businesses develop to identify and qualify manufacturers and suppliers of critical components that have already been evaluated to ensure all business and quality/compliance standards are met. The vendor can jump in and ramp up production should a Tier 1 or Tier 2 supplier not be able to deliver.

Markets with a history of volatility and disruptions, such as Electronics and Automotive, should prioritize creating an AVL for all critical components (and even some minor ones). Then, when something happens to the original supply, an approved vendor can quickly jump in and ramp up to maintain production demands.

Why should you use an AVL?

Approved vendor lists empower manufacturers to minimize disruptions, gain greater control over their supply chain, reduce costs, maintain production efficiencies, and, last but not least — maintain relevant compliance and regulatory standards.

AVLs are invaluable for several reasons, including:

- Streamlined procurement - From eliminating engineers having to conduct non-value-add tasks like sourcing parts to speeding up new supplier agreements and production, AVLs can boost your bottom line. According to research by Tech-Clarity, engineers spend 33% of their day on non-value-added engineering work. Worse yet, 1/3 of that time is spent working with outdated information. The delays and costs associated with finding a replacement part using outdated information can compound quickly when you're already facing a supply chain disruption.

- Speed to market - When there’s trouble brewing in your supply chain, hitting the ground running with an approved and qualified provider will help shorten lead times and minimize costly delays.

- Quality control - Working with suppliers that already meet your quality standards helps ensure you won’t produce many warranty-claim-inducing products on the next run.

- Cost management - If one supplier increases its rates, having a competitive or cheaper alternative at the ready can enable manufacturers to switch vendors to save costs without disrupting the supply chain or production.

- Resiliency - The past few years have taught us that cost is not the only consideration when sourcing materials. Maintaining enough supply to keep production moving amid industry and other disruptions is crucial to any manufacturer’s ability to remain operating and competitive.

Plus, finding replacement parts isn’t always easy

Form-fit-function (FFF) must be carefully evaluated when sourcing alternatives, as all three are essential to finding a workable solution.

- Form - Factors such as the dimensions, footprint, package size, shape, or other visual elements

- Fit - How the component aligns with specifications set by engineering in the design phase and can connect with other elements in the component

- Function - How the component performs compared to its intended design

Essential to help minimize supply chain disruptions, replacement parts typically fall into three categories (the fourth is custom, but that should be a last resort due to cost and time implications):

Replacement Component Categories

| Type |

Drop-in replacement |

Functional equivalent |

Functional alternative |

| Similarity to original | The same footprint, pinout, and symbols as the original, so it’s interchangeable and easy to swap | Almost identical electrical specifications; may be available in another package or with additional features not needed for your design | Notable differences in form, fit, or function with the ability to be configured to perform the product requirements |

| Design implications | No modifications needed | Little to no modifications; may require some testing/validation | Likely requires design modifications, testing and qualification |

| Cost implications | Depends on availability and other supplier pricing | Depends on availability, supplier pricing | Depends on how extensive design changes are |

| Other considerations | Usually the fastest, most cost-effective solution | Could be a variant of your MPN | Design edits could render the original part obsolete |

Drop-in replacement - Having a set of components you can use interchangeably with your given part number without having to re-test, re-qualify, or make any engineering or production change is the easiest and most efficient way to substitute a part in a time of need. Drop-in replacements have the same footprint and symbols as your original part, making them the fastest way to replace a part and keep production moving.

Functional equivalents - A functional equivalent could be almost identical to the one you’re replacing, with similar specs and footprints, but maybe in a different package. These parts could be a variation of your manufacturer part number (MPN). The engineering team will need to evaluate the equivalent and make design changes, which will incur costs and production time delays.

Functional alternatives - These parts may have greater power limits, a different footprint and schematic than your original component, or other features outside your original design specifications. But the part can perform the required functions of your design. Your engineering team will need to evaluate and test any functional replacements, and the design will likely need to be tweaked. Remember, once the design is modified to suit the functional equivalent, it may no longer work with the original part and its requirements.

Because most discrete semiconductors are available in standard specs and packages, it should be relatively easy (in most cases) to find a drop-in replacement, functional equivalent, or functional alternative. You may even end up with a better design thanks to a superior component.

On the other hand, custom components will be nearly impossible to find a suitable replacement without an extensive redesign is the only workable solution.

Having an approved vendor list in your back pocket for those components that can be replaced easily is crucial to your success.

Tips for creating & maintaining your AVL

Whether you’re just getting started or already have an AVL in place, here are some tips to optimize your list and prevent costly delays:

Enlist your team - Collaborate with engineering and sales teams to prioritize finding backups for your high runners and products with ambitious sales targets. Your team could also provide valuable anecdotal feedback that could save you from preferring a vendor they’ve already heard horror stories about or had negative encounters with.

Get input from your distributors - Your distributors constantly monitor market conditions and often have the digital tools and resources to help you quickly source top-quality crosses for your specific components. Of course, using authorized distributors is essential to help ensure you only source quality parts from the original suppliers.

Request indicative quotes - To ensure the vendor’s pricing is competitive (or at least see the difference), ask each potential supplier to provide indicative or informational quotes on your key components. Use this information to create more accurate comparisons when creating and evaluating your list.

Get component samples - Request samples from your list of potential vendors or their distributors, then task your engineers with testing them against their technical requirements and quality standards.

Set up Google Alerts for your preferred list - It only takes a few minutes to set up a Google alert for each vendor on your list. This way, if they are in the news for something that’s a red flag (pending bankruptcy, customer lawsuit, natural disaster, etc.), you’ll know about it quickly and can make any necessary adjustments.

Validate and update your list regularly - Establish a process for updating your AVL a few times a year or whenever you have significant changes in your component needs. Here are a few items to verify and update:

From your organization:

- Part changes or modifications for existing products

- Specs and requirements for new designs

- Regulatory changes that impact suppliers

- Product roadmap for the next year

From the vendor:

- Pricing increases

- Availability of materials

- Capacity changes

- Return policy updates

- Quality changes

- End-of-life (EOL) announcements for your alternatives

- Customer reviews and feedback (including from your team)

Communicate any vendor changes to your team - Adding new vendors? Removing some from your list? Ensure your entire team is briefed on any AVL edits and their implications.

Minimizing supply chain risk requires ongoing effort for manufacturers. Fortunately, tools like APLs are a great way to improve resiliency and reaction times when one component’s availability is in jeopardy.

If you need to source semiconductor components to replace backlogged parts quickly, MCC has the dedicated resources to review your BOM and find the appropriate solutions to help you minimize production delays.

We can also conduct crosses on bulk parts lists. Contact our team for help finding the ideal replacement for your essential components.

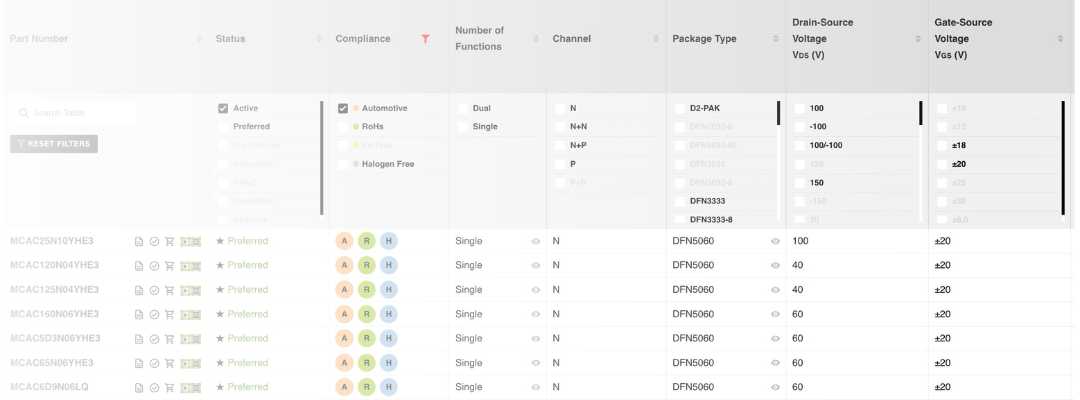

If you’d like to search for a handful of components, you also have the option to use the tools on our website to find crosses and related products.

Have questions or need assistance? Use the MCC website chatbot.

.png?width=50&height=50&name=mcc%20150x150%20(1).png)