Understanding Rectifier Diodes:

A Complete Guide for Engineers

- Topics Covered in this Guide

- Understanding Rectifier Diodes

- What Are Rectifier Diodes?

- What Are Rectifier Diodes Used For?

- How Do Rectifier Diodes Work?

- Core Functions of Rectifier Diodes

- Four Key Categories of Rectifier Diodes

- Choosing the Right Rectifier for Your Application

- Rectifier Diodes Are Available in a Wide Variety of Packages

- Application Examples for MCC Rectifier Diodes

Understanding Rectifier Diodes

Rectifier diodes are key components that convert alternating current (AC) into direct current (DC), allowing current to flow in only one direction. Their role is essential in power conversion applications across consumer electronics, industrial equipment, and automotive systems.

What Is a Rectifier Diode?

A rectifier diode is a semiconductor device that allows electrical current to pass in one direction (forward bias) while blocking it in the opposite direction (reverse bias). This unidirectional behavior makes rectifier diodes essential in AC-to-DC power conversion systems.

Unlike small signal diodes, rectifier diodes are designed to handle significantly higher current levels—typically defined by a forward current greater than 500mA. Their robust construction enables them to support a wide range of power applications, from consumer electronics to industrial and automotive systems.

Key Characteristics of Rectifier Diodes:

- Enable one-way current flow for rectification

- Handle high current loads with low forward voltage drop

- Available in multiple speed classes (Standard, Fast, Super-Fast, Schottky), each optimized for specific switching frequencies and efficiency needs

Schematic symbols for a diode

Rectifier Diode Applications and Use Cases

Rectifier diodes play a foundational role in modern power systems by enabling unidirectional current flow, essential for converting alternating current (AC) into usable direct current (DC). Whether stepping down voltage in industrial machinery or regulating current in compact consumer electronics, rectifiers ensure stable, efficient energy delivery across a range of demanding environments.

Because they are designed to handle high current and voltage demands, rectifier diodes are critical in applications such as:

Key Characteristics of Rectifier Diodes:

- Automotive: In high-efficiency charging systems like the Fast EV Charger, rectifier diodes help manage rapid AC-to-DC conversion, supporting high-speed charging while maintaining thermal performance and reliability under varying grid conditions. They are also essential in Front & Rear LED Lights, LED Backlights for touch screens and cameras, and Electric Power Steering (EPS), where they support regulated current, EMI suppression, and consistent system response.

- Computing: From internal cooling systems like DC fans to Uninterruptible Power Supplies (UPS), rectifier diodes ensure consistent current delivery and protect against system interruptions or power anomalies.

- Industrial: In rugged industrial environments, rectifiers are key components in AC-DC Power Supply Units. These systems depend on rectifiers to convert raw AC input into tightly regulated DC output, ensuring consistent operation of mission-critical equipment.

- Consumer Electronics: Compact and efficient, rectifier diodes are integrated into a variety of everyday devices. They manage signal and power conversion in Class D amplifiers, enable Simple Flyback Topology LEDs, and maintain power flow in AC-DC adaptors, all while minimizing heat and conserving energy.

In each of these applications, rectifier diodes are not only performing the crucial task of rectification, they are contributing to overall system efficiency and performance.

While rectifiers can support robust operation, true high-reliability performance depends on selecting the right diode for the application environment. MCC offers AEC-Q101 qualified and application-specific rectifiers, such as those designed for automotive systems or photovoltaic (PV) circuits, where enhanced reliability under high thermal or electrical stress is essential.For general-purpose use, reliability is ensured by adhering to recommended electrical and thermal limits and by using rectifiers within their specified operating margins.

How Do Rectifier Diodes Work?

During forward bias, the diode conducts current with minimal voltage drop. Under reverse bias, it blocks current until breakdown voltage is reached. This unidirectional behavior enables the conversion of alternating current (AC) to direct current (DC), a fundamental function in power electronics. The diagram below illustrates the I-V characteristics of a typical rectifier diode. In forward bias, current begins to flow once the threshold voltage is exceeded. In reverse bias, current remains blocked until the breakdown voltage is reached:

Categories of rectifier diodes differ in their recovery characteristics, which are critical for switching performance. For PN-junction rectifiers (Standard, Fast, Super-Fast), switching speed is defined by reverse recovery time (TRR). Schottky diodes, however, are majority-carrier devices with negligible reverse recovery, making them ideal for high-speed switching applications.

Main Functions of a Rectifier Diode

Rectifier diodes play a vital role in power conversion by enabling unidirectional current flow, allowing electrical current to pass only in the forward direction while blocking reverse flow. This ensures stable DC output and prevents reverse current that could disrupt circuit operation.

Beyond directing current, MCC rectifiers are specifically designed to handle high current loads, making them suitable for demanding applications such as power supplies, inverters, and motor drives. Their rugged construction ensures consistent performance even under significant thermal and electrical stress.

To further optimize efficiency, MCC rectifier diodes feature a low forward voltage drop. This minimizes power loss during conduction and reduces thermal stress on the component, an essential characteristic for applications focused on energy savings and compact design.

Types of Rectifier Diodes Explained

At MCC, rectifier diodes are classified into four primary categories, each defined by key performance parameters such as switching speed, forward voltage drop, and overall efficiency, especially in applications where forward current exceeds 0.5A. This current threshold serve as dividing line between small signal diodes and rectifiers in our portfolio.

The four rectifier types are engineered to meet the unique demands of different applications, from low-cost AC-DC conversion to high-speed, EMI-sensitive designs. These categories include:

Key Characteristics of Rectifier Diodes:

- Standard Recovery

- Fast Recovery

- Super-Fast Recovery

- Schottky Barrier

Each type is designed to optimize trade-offs between speed, breakdown voltage, thermal performance, and power efficiency, providing engineers with a targeted approach to selecting the ideal rectifier for their specific design environment.

Difference Between Small Signal and Rectifier Diodes

At MCC, diodes with a forward current less than 0.5A (500mA) are classified as small signal diodes, typically used in applications such as signal processing, voltage clamping, and waveform shaping. Rectifier diodes, with forward currents exceeding 0.5A, are designed for power conversion and typically feature higher voltage ratings and more robust packages

This forward-current-based classification helps engineers distinguish between components suited for low-power signal control and those built for high-current AC-DC rectification. It also supports informed diode selection by balancing size, performance, and thermal requirements across various circuit designs.

What Are the Advantages of Rectifier Diodes?

Rectifier diodes offer an ideal balance of performance and simplicity. Their ability to reduce system complexity while maintaining electrical efficiency makes them indispensable in power conversion design. From entry-level consumer products to rugged industrial systems, rectifiers deliver consistent performance at a fraction of the cost of more complex alternatives:

- Cost-Effective: Lower component costs compared to alternatives like MOSFETs or IGBTs

- Simple Integration: Achieve functions like OR-ing and polarity protection, freewheeling with minimal circuitry

- Versatile Design Options: Available in a wide range of current/voltage ratings and package types

- Application Breadth: Supports both consumer and industrial needs

- Low Forward Voltage (Schottky): Ideal for high-efficiency, low-voltage designs

How to Choose the Best Rectifier Diode for Your Circuit

Selecting the right rectifier isn’t just about matching voltage and current. Engineers should also consider factors that influence long-term reliability and circuit efficiency. Understanding your application’s switching environment and expected load profiles can help narrow down the optimal diode category and package. Key consideration includes:

- Application Frequency: Use standard diodes for low-frequency applications, choose Schottky or super-fast recovery diodes for high-speed switching

- Recovery Time: Affects switching speed and EMI

- Thermal Considerations: Select packages with appropriate heat dissipation for sustained operation

- Package & Form Factor: Choose between surface-mount or through-hole, leaded or leadless packages based on assembly needs

- Automotive Compliance: Ensure AEC-Q101 qualification for automotive-grade applications

Best Rectifier Diode Types for Low-Frequency AC to DC Conversion

Rectifier diodes are not a one-size-fits-all solution—their effectiveness depends on how well they match the application’s frequency, power demands, and circuit design. For example, in low-frequency applications such as industrial AC-DC converters or consumer power supplies, standard recovery rectifiers offer a cost-effective and dependable solution. The graphic below illustrates typical use cases for rectifier diodes in these scenarios, highlighting their role in managing current flow, ensuring voltage regulation, and maintaining system stability.

.png?width=1000&height=420&name=Rectifier%20Application%20-%20%20mcc%20semi%20-%20micro%20commercial%20components%201000x420%20(1).png)

How to Evaluate Rectifier Diode Performance

Understanding key electrical parameters is essential when selecting a rectifier diode for reliable and efficient operation. These performance metrics directly impact thermal behavior, efficiency, and long-term stability:

.png?width=800&height=250&name=Key%20Parameters%20of%20a%20Rectifier%20Diode%20-%20MCC%20Semi%20-%20Micro%20Commercial%20Components%20800x250%20(1).png)

- Forward Voltage Drop (VF): Lower VF reduces conduction losses, which is especially important in power-efficient or thermally constrained designs.

- Breakdown Voltage (VBR): The maximum reverse voltage the diode can withstand without failing. Always select a VBR well above your application’s peak reverse voltage.

- Reverse Leakage Current (IR): Small leakage is normal under reverse bias, but elevated IR can indicate diode degradation due to overvoltage or thermal stress.

- Thermal Runaway: A dangerous condition where heat generation exceeds dissipation, causing a self-reinforcing temperature rise. Proper derating, thermal design, and heatsinking are critical to avoid this failure mode.

Why Do Rectifier Diodes Fail? Common Causes and How to Prevent Them

Even robust rectifier diodes can fail when subjected to excessive electrical or thermal stress. To ensure long-term reliability, it’s important to understand how early-stage stress can evolve into permanent failure:

- Overcurrent and Thermal Overload: Sustained operation above rated current or poor heat dissipation can elevate the diode’s junction temperature. If unchecked, this may lead to thermal runaway—a self-reinforcing condition where rising temperature accelerates degradation until failure

- Parameter Drift: Before complete failure occurs, a diode may exhibit shifts in electric characteristics such as increased reverse leakage current or forward voltage drop. These shifts can serve as early warning signs of stress-induced wear or fatigue.

- Short Circuits: Continued thermal or electrical stress without mitigation can cause an internal breakdown, leading to a short circuit. This results in total loss of rectification and potential collateral damage to surrounding circuitry.

By recognizing this failure progression—from thermal stress to parameter degradation to electrical failure—engineers can implement appropriate derating, thermal management, and protective design strategies to extend diode lifespan and maintain system stability.

How to Select the Right Rectifier Diode for Your Design

Choosing the right rectifier diode involves more than just voltage and current ratings. For reliable operation and long-term performance, engineers must consider electrical margins, thermal design, and switching behavior. Key selection factors include:

- Input Voltage (AC RMS and Peak):

Ensure the reverse voltage rating (VRRM) of the diode exceeds the peak AC input voltage with adequate margin. For example, a 230V AC line may require a 600V or 800V rated diode. - Output Current (Average and Peak):

Select a diode rated for continuous load current with headroom for peak inrush or transient conditions.

- Recovery Speed:

Match to the switching frequency of your circuit. Use standard recovery for low-frequency applications and fast/super-fast recovery for high-frequency or EMI-sensitive designs.

- Package Type:

Aligh the package with board layout and thermal requirements. Consider surface mount for compact designs or TO-220/TO-247 for higher power dissipation. - Automotive Compliance:

For automotive or mission-critical systems, select AEC-Q101 qualified diodes to meet reliability standards.

Rectifier Diode Packages: Types and Selection Guide

Rectifier diodes are available in wide range of package types to meet the needs of both high-power and space-constrained applications. Commonly used in AC-DC conversion, voltage regulation, and power switching such as SMA, SMB, SMC, SOD-123, and SOD-323 are optimized for specific current levels, thermal profiles, and assembly methods.

MCC offers an extensive portfolio of rectifier diode packages:

- Axial Leaded: DO-41, DO-15, R6 – ideal for traditional, robust through-hole designs

- Through-Hole Power: TO-220, TO-247, TO-264 – suited for high-current and high-voltage systems requiring efficient heat dissipation

- Surface Mount (SMD): SMA, SMB, SMC, SOD-123, SOD-323 – compact, automation-friendly solutions for modern PCB layouts

- Flat Lead Packages: SMAF (DO-221AC), SMBF – combining low profile height with excellent thermal performance

- Leadless: DFN5060 – optimized for dense board layouts and low inductance designs

No matter your thermal, mechanical, or layout constraints, MCC’s package offerings help you optimize performance, power handling, and board space efficiency.

MCC Rectifier Diode Portfolio Overview

MCC provides a comprehensive range of rectifier diodes designed to meet the demands of power conversion across consumer, industrial systems, and automotive applications. Our product lineup spans four key technologies—Standard Recovery, Fast Recovery, Super Fast Recovery, and Schottky Barrier—with thousands of part options across wide range of voltage rating, current capacities, and package types.

For automotive-grade designs requiring high reliability and AEC-Q101 compliance, MCC offers a targeted selection: approximately 25% of our Standard Recovery portfolio and 10% of our Super Fast Recovery lineup are AEC-Q101 qualified. These devices are engineered for harsh operating environments and are ideal for mission-critical applications such as automotive power systems, battery charging, and LED lighting.

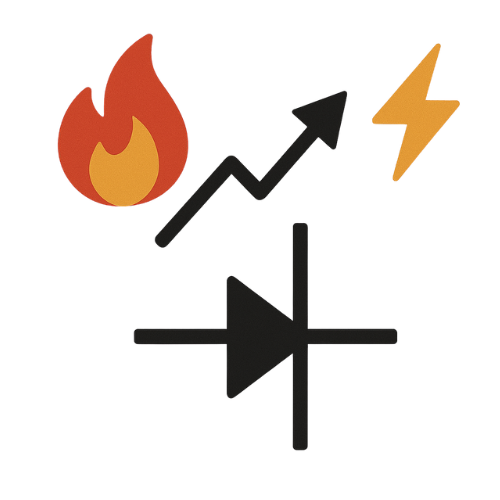

Standard Recovery Rectifier Portfolio Overview

MCC’s Standard Recovery Rectifier portfolio offers a robust selection of devices optimized for low-frequency AC-to-DC conversion. With over 190 part numbers available—including automotive-grade options (AEC-Q101 qualified)—this portfolio is well-suited for cost-effective power rectification across industrial, consumer, and automotive applications.

Our devices span a broad voltage range from 400V to 4000V, with commonly used models rated at 400V, 600V, 800V, and 1000V. High-voltage options—particularly in the 1600V to 2000V range—are also widely used in motor drives, battery chargers, and welding machines.

Rectifiers in this category support forward currents ranging from 1A to 60A, including:

- 1A to 3A: ideal for general-purpose AC-DC designs

- 20A to 25A: Common in 600W applications

- 30A to 60A: Designed for high-power industrial systems

To meet layout and thermal requirements, MCC offers this portfolio in a wide selection of packages:

- Surface-mount: SMA, SMB, SMC

- Compact SMD: SOD-123, SOD-323

- Through-hole: TO-263, TO-220, TO-247

- Flat-lead: SMAF, SMBF

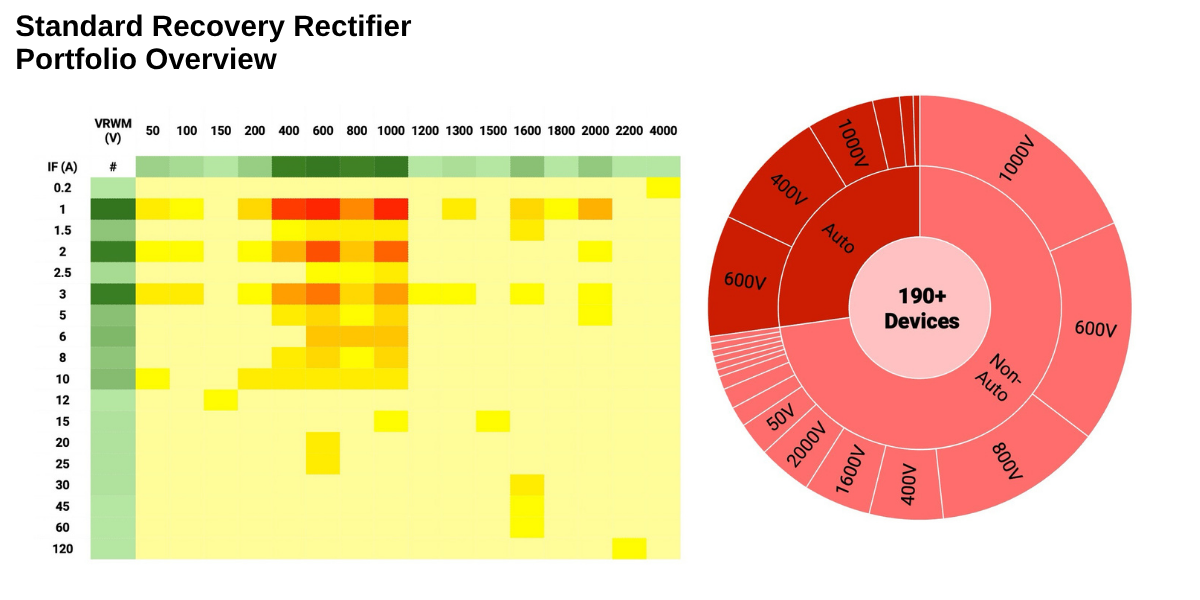

The heatmap below visualizes common combinations of reverse working voltage (VRWM) and package types, highlighting where MCC offers multiple options to support flexible, application-specific design. Whether you need a low-profile SMD part for consumer electronics or a high-current TO-247 for industrial power, the standard recovery lineup provides a reliable, accessible solution.

Fast Recovery Rectifier Portfolio Overview

MCC’s Fast Recovery Rectifier portfolio is designed for AC-DC conversion and switching applications that demand faster performance than standard diodes—without compromising stability or cost-effeciency. With 80+ devices available, this product family supports a broad range of power and voltage requirements across industrial and commercial systems.

These rectifiers are optimized for use in non-automotive applications and deliver reliable reverse recovery times in the 50ns to 500ns range. They are a strong fit for mid-frequency designs, such as power factor correction circuits, switching power supplies, and inverter stages.

The portfolio covers:

- Voltage ratings: 200V to 1000V

- Current ratings: 0.5A to 10A

- Typical Use Range: 1A to 3A for compact, efficient rectification

To accommodate different power densities and board configurations, MCC provides fast recovery rectifiers in a wide array of package types:

- Surface-mount: SMA, SMB, SMC

- Compact SMD: SOD-123, SOD-323

- Axial leaded and through-hole: DO-41, TO-220, TO-247

The graphic below showcases the VRWM vs. package heatmap, allowing engineers to quickly pinpoint available combinations and evaluate options based on footprint, thermal performance, and mounting preference.

Whether you’re designing for compact consumer power modules or larger industrial systems, MCC’s fast recovery rectifiers offer a dependable balance of speed, efficiency, and integration flexibility.

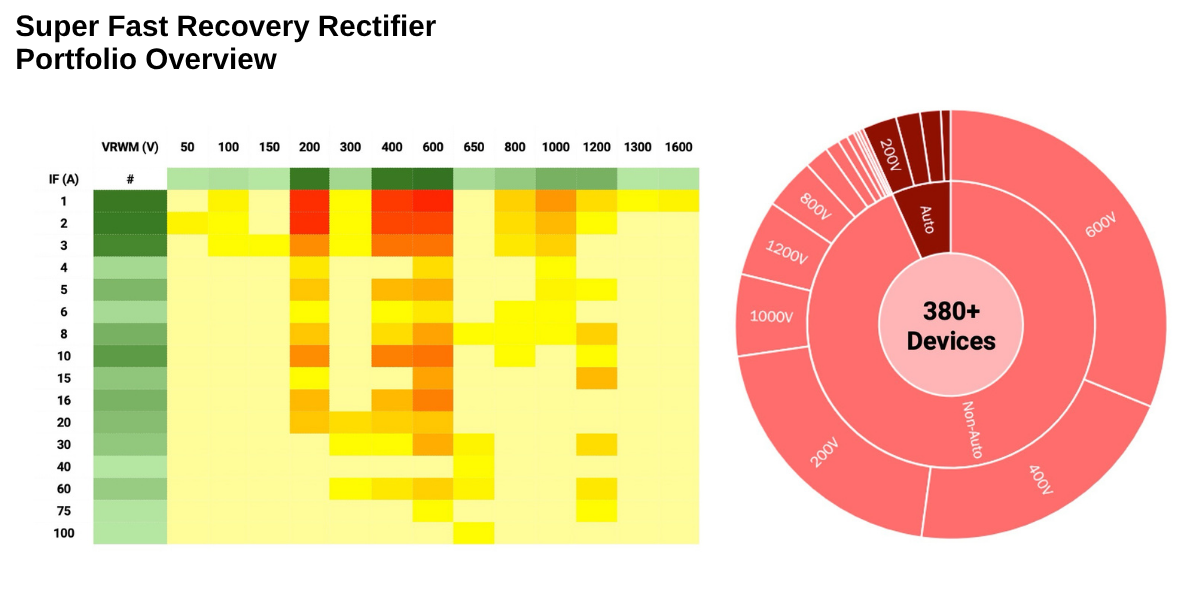

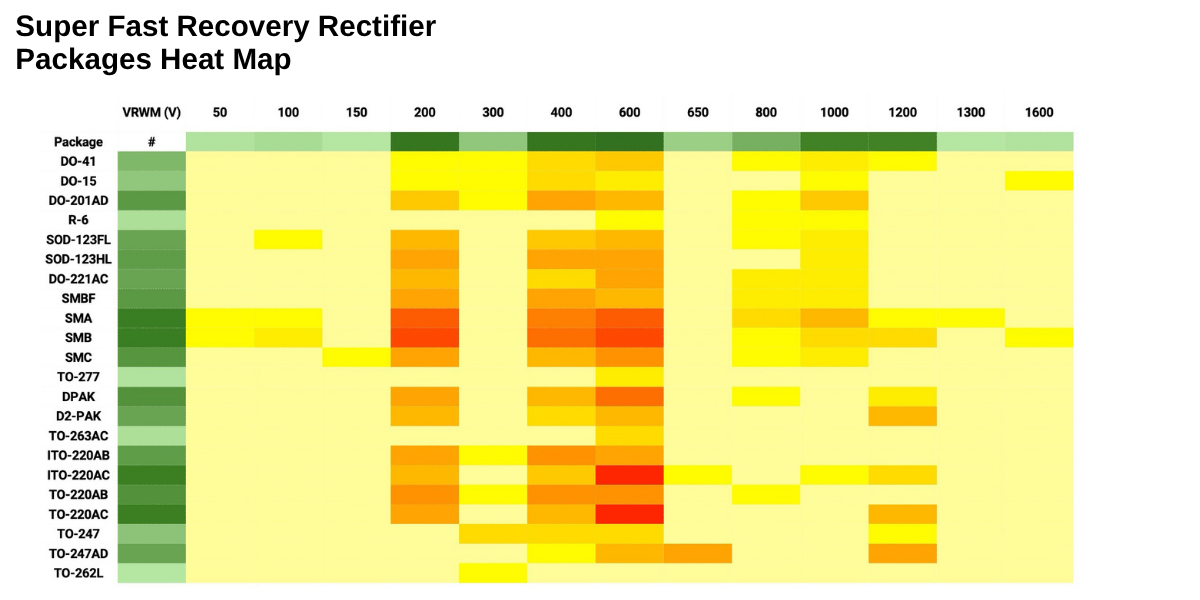

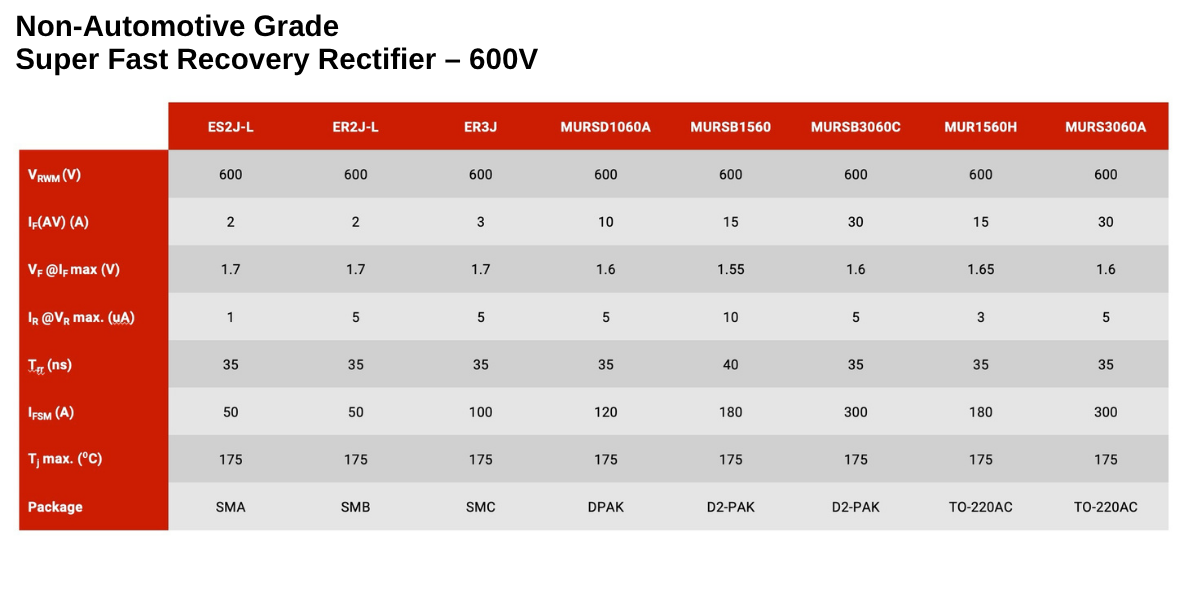

Super Fast Recovery Rectifier Portfolio Overview

MCC’s Super Fast Recovery Rectifier portfolio is designed for high-speed, high-efficiency power applications where low reverse recovery time and EMI reduction is critical. With 380+ devices available, this lineup is ideal for noise-sensitive, high-frequency switching designs.

These diodes are designed for reverse recovery times under 150ns, with some parts reaching as low as 35ns, making them ideal for flyback converters, telecom power systems, and high-frequency AC-DC designs.

TKey specifications include:

- Voltage ratings from 200V to 600V

- Current ratings from 1A to 100A, with popular usage from 1A to 30A

- Approximately 10% of the portfolio is AEC-Q101 qualified for automotive use

A broad mix of package options supports both board density and thermal efficiency:

- Surface-mount: SMA, SMB, SMC, flat-lead versions

- Compact SMD: SOD123

- Industrial & power: DPAK, D2PAK, DPEG

- High-current through-hole: TO-220, TO-247, RSIC

The heatmap below highlights the availability of package types across various VRWM levels, enabling quick selection based on voltage requirements and thermal design constraints.

Whether you’re replacing Schottky diodes for better EMI performance or designing for demanding power density targets, MCC’s super fast recovery rectifiers provide a high-speed, high-reliability solution ready for next-generation systems.

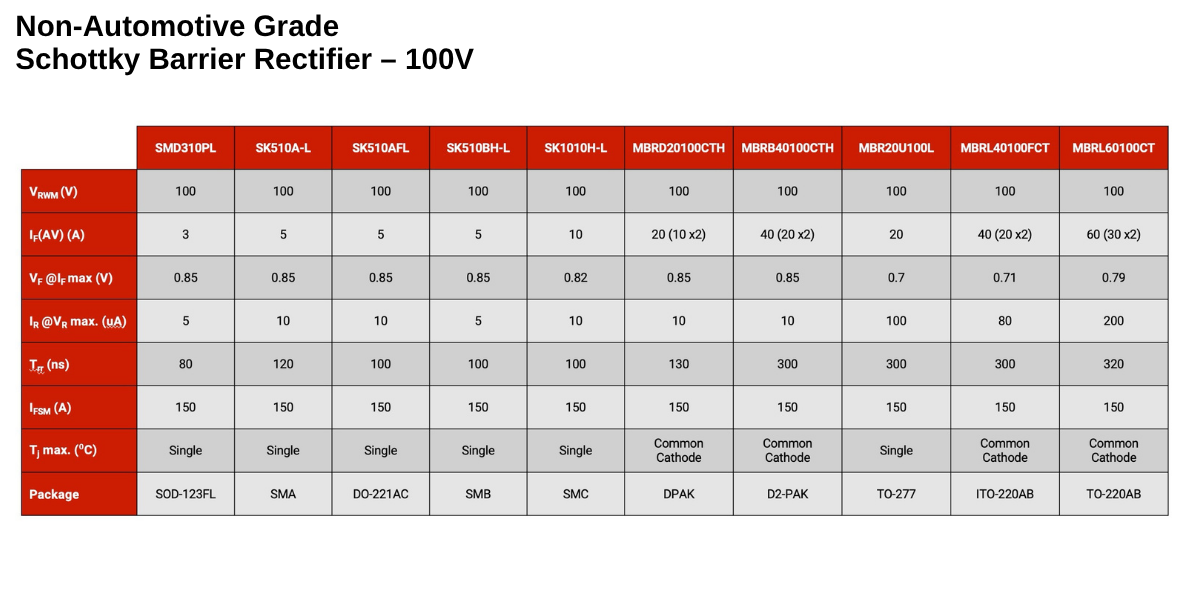

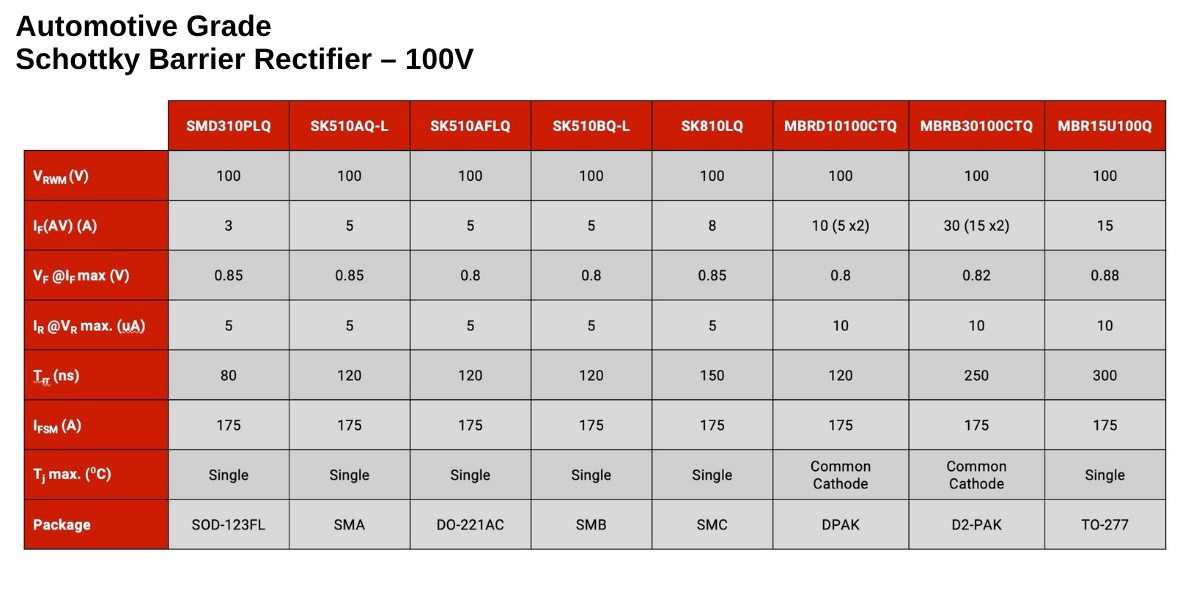

Schottky Barrier Rectifier Portfolio Overview

MCC’s Schottky Barrier Rectifiers are optimized for high-efficiency, low-voltage power applications where fast switching and minimal power loss are critical. With over 670 devices available, this portfolio supports a wide variety of compact and high-performance designs in both consumer and industrial markets.

These diodes are well-suited for DC-DC converters, battery-powered devices, and OR-ing circuits, offering reverse recovery times under 20ns and low forward voltage drops (typically <1V) for superior efficiency.

Portfolio highlights include:

- Voltage ratings from 15V to 300V

- Current ratings from 1A to 100A

- Common configurations include 1A to 10A at 40V to 200V, with dual-channel options supporting up to 20A

A versatile range of package options supports everything from compact PCBs to high-current industrial needs:

- Surface-mount: SOD-123, SOD-323, SMA, SMB, SMC

- Flat-lead & leadless: DPAK, DFN5060

- Through-hole & high power: TO-220, TO-277, TO-227

- Industrial: DPAK, D2PAK, with full-pack isolated versions available

The heatmap below displays available package and VRWM combinations, helping engineers visualize the breadth of choices for current density, efficiency, and board layout.

Whether you’re designing for power supplies, DC switching stages, or portable electronics, MCC’s Schottky rectifiers offer a low-loss, high-speed solution with reliable thermal performance and compact form factor flexibility.

Real-World Applications of MCC Rectifier Diodes

MCC rectifier diodes are widely used across a broad spectrum of AC-DC and DC-DC power applications, each requiring specific diode types based on switching speed, current handling, and voltage requirements. Whether you’re designing for high-frequency RF circuits or rugged industrial power systems, MCC offers targeted rectifier solutions that support performance, efficiency, and reliability.

Common Use Cases by Diode Type:

- RF Demodulation: In RF front-end circuits, Schottky barrier and super fast recovery rectifiers are preferred for their ultra-fast switching and low forward voltage—essential for signal clarity and minimal delay in demodulation processes.

- ESD Protection: For sensitive interfaces and IO ports, Schottky barrier rectifiers are commonly used as ESD clamping elements due to their fast response time and low clamping voltage.

- OR-ing Circuits: In some low-speed, cost-sensitive designs, standard recovery rectifiers may be used for OR-ing. However, for high-speed or efficiency-critical OR-ing circuits, Schottky or Super-Fast recovery diodes are generally preferred due to their lower forward voltage and faster switching.

- Freewheeling Diodes: In motor drives and inductive load circuits, super fast recovery and Schottky rectifiers serve as efficient freewheeling diodes, protecting against voltage spikes and maintaining energy recirculation.

- DC-DC Converters: Schottky rectifiers are ideal for use in switching regulators and buck/boost converters due to their low forward voltage and minimal switching losses.

- AC-DC Power Conversion: From battery chargers and UPS systems to industrial power supplies and welding equipment, MCC offers high-power rectifiers (e.g., R6 and TO-220 packages) designed for reliable AC-DC rectification in demanding environments

These examples reflect the versatility of MCC’s rectifier portfolio—engineered to meet the nuanced requirements of real-world power system design.

Additional Resources

Rectifier Diodes Brochure

Our detailed brochure offers an extensive overview of rectifier diodes, covering their core characteristics, key benefits, and current technologies used in AC to DC power conversion.

Application Guides

Explore the broad range of applications for rectifier diodes. From power supplies and battery chargers to motor drives and welding machines, see how MCC rectifiers support reliable AC to DC conversion across industries.

Complete Product Catalog

Effortlessly browse our comprehensive catalog to find the right rectifier diodes for your design. Detailed specifications and package options help you choose with confidence.

Contact MCC for advanced solutions that deliver a competitive edge.

MCC is a manufacturer of high-quality discrete semiconductors to the consumer markets © MCC. All Rights Reserved · 2025