Thermal Management: A Guide to Greater MOSFET Performance and Cooling

Prevent Overheating and Enhance Reliability, Longevity & Safety with Dual-Side Cooling

What is Thermal Management?

In electronic systems, heat is a natural byproduct of energy conversion and operation. However, uncontrolled temperatures can lead to inefficiencies, failures, or even damage to sensitive components. Thermal management aims to balance heat generation and dissipation to ensure stable conditions for optimal performance, safety, and longevity.

At its core, electronic thermal management leverages principles of thermodynamics, including:

- Conduction: Heat transfer through solid materials

- Convection: Heat transfer through fluid movement like air or liquid

- Radiation: Heat transfer through electromagnetic waves

These concepts help control how heat moves within a system, whether dissipated, stored, or redirected, ensuring systems operate efficiently and reliably.

By applying these techniques and technologies, engineers can effectively regulate temperatures, maintaining functionality for everything from small devices to complex operations.

Why Thermal Management Is Critical for Electronic Devices

Managing the excess heat electronic devices and circuits produce during operation is crucial to prevent damage to sensitive components. Thermal management systems are designed to keep temperatures within a safe range, bridging the gap between the operational requirements of these systems and the demands of their industries.

Here’s why effective thermal management is essential for modern electronics:

- Preventing Overheating

While all electronics produce some heat, high-powered systems, such as computers or electric vehicles, generate significant amounts. If left unmanaged, overheating can deteriorate components, shorten the lifespan of devices, and lead to costly repairs or replacements.

- Enhancing Performance

Devices like smartphones and laptops often slow down or experience heat-related performance issues. Thermal management ensures these systems operate at peak efficiency, avoiding throttling and maintaining consistent functionality.

- Ensuring Safety

For advanced systems like vehicle electronics, aircraft controls, or military equipment, overheating isn’t just inconvenient, it can lead to serious safety risks like fires or system failures. Effective heat regulation minimizes these hazards and protects users.

- Supporting Industry-Specific Applications

When it comes to thermal regulation, each industry has distinct requirements. Automotive systems, consumer electronics, and industrial equipment demand customized solutions to ensure ideal performance across varying operational environments.

- Enabling Compliance and Reliability

Adhering to thermal standards is crucial for regulatory compliance. Proper heat management ensures customer safety and satisfaction while safeguarding manufacturers against liability.

As devices continue to evolve with greater complexity and higher power demands, thermal management remains a cornerstone of safe and reliable operation across all sectors.

How Does Electronic Thermal Management Work?

Thermal management systems operate by actively or passively controlling how heat flows within a device or system. The primary goal is to prevent overheating by transferring heat away from critical components where it is safely dissipated or stored.

This process involves thermal modeling and analysis, as well as implementing specialized tools, materials, and designs tailored to the specific thermal demands of the application.

Core Techniques in Thermal Management:

- Passive Cooling: Devices such as heat sinks, thermal pads, and insulating materials rely on natural heat transfer mechanisms to dissipate excess heat without requiring external power.

- Active Cooling: Systems like fans, liquid cooling setups, and thermoelectric coolers actively remove heat by circulating air or fluids, providing more robust temperature control for high-performance applications.

- Thermal Conductivity Enhancers: Materials such as thermal paste or graphite sheets improve heat transfer between surfaces, minimizing hotspots and maximizing efficiency.

- Airflow Optimization: Strategic enclosure design allows for proper ventilation, ensuring cooler air enters the system while hot air is expelled.

- Temperature Monitoring and Feedback: Sensors integrated into systems measure temperature changes in real time, enabling dynamic adjustments like increasing fan speed or activating cooling systems during peak loads.

By employing these methods, thermal management systems deliver consistent operation and reduce risks such as overheating or component failure.

How Poor Thermal Management Impacts Device Reliability and Safety

Electronic devices must operate within specific temperature ranges to function reliably. When these boundaries are exceeded, several adverse effects can occur, including:

- Reduced Lifespan: Devices operating near their temperature limits often experience accelerated wear and tear. This shortened lifespan results in frequent replacements and increased costs for users.

- Safety Risks: Excess heat can make devices too hot to handle, posing significant safety hazards to users. In cases where extreme overheating occurs, there’s a risk of burns or even fire.

- Operational Downtime: Overheating can lead to unexpected shutdowns or malfunctions, causing inconvenience and productivity loss. This is especially critical in industries where reliability is paramount, such as automotive, consumer electronics, and industrial systems.

- Reputation Damage: For consumer products, thermal issues can harm sales and damage the company’s reputation. Customers expect dependable performance, and failing to meet these expectations can lead to negative reviews and decreased loyalty.

In sectors where safety and reliability are non-negotiable, implementing effective thermal management solutions is not just beneficial but essential.

Dual-Side Cooling Technology Drives Exceptional Thermal Performance

MCC’s DFN5060 MOSFET package with dual-side cooling (DSC) is a game-changer for power electronics. Our advanced power MOSFET technology offers exceptional thermal performance due to its optimized package architecture, which incorporates a split-gate trench design and a copper clip for enhanced heat dissipation.

These features significantly reduce thermal resistance and improve efficiency, making it a superior choice for demanding applications.

How Does Dual-Side Cooling Work?

The DFN5060 package with dual-side cooling (DSC) introduces a cutting-edge solution for heat dissipation. This design features thermal pads on both the top and bottom surfaces, combined with an additional heat transfer path on the top, achieving an impressively low junction-to-case thermal resistance.

This innovative approach offers a significant advantage in managing temperature rise compared to traditional DFN5060 packages. The dual-side cooling design enables quicker and more efficient heat removal, minimizing overheating risks and extending the lifespan of electronic components.

By utilizing this technology, manufacturers can maintain optimal thermal regulation, meeting the increasing demand for durable and reliable electronic systems.

Engineered for Efficiency and Longevity

The DFN 5x6 package with DSC represents a major advancement in MOSFET design, delivering superior performance over traditional packages. Its innovative features reduce thermal resistance and enhance heat dissipation, which is crucial for sustaining reliability and efficiency in power-demanding scenarios.

Key Features:

- Innovative Copper Clip Technology: Improves thermal conductivity for better heat transfer.

- Low Junction-to-Case Thermal Resistance: Facilitates efficient heat transfer.

- Minimal Temperature Rise: Maintains reliable performance during operation.

- Dual-Sided Cooling Pad: Enhances heat dissipation from both top and bottom surfaces.

- Significant Thermal Resistance Improvement: Delivers up to a 52% improvement in steady-state thermal resistance compared to conventional MOSFETs.

Benefits:

- Maximized Thermal Efficiency: Ensures optimal performance in diverse applications.

- Extended Device Lifespan: Improves longevity through effective heat management.

- Higher Power Densities: Supports greater output capabilities.

- Compact and Reliable Systems: Enables smaller, more dependable electronic designs.

- Versatile Applications: Features scalable thermal management for various uses.

- Superior Heat Sink Efficiency: Optimizes overall cooling performance.

Get Enhanced Thermal Performance from Top to Bottom

The DFN5060 with dual-side cooling features thermal pads on the top and bottom, with an additional transfer path on the top for junction-to-case thermal resistance as low as 0.67⁰C/W. This feature offers a better temperature rise margin than traditional DFN5060 packages.

Ideal Applications for Dual-Side Cooling Technology

Our DSC MOSFET solutions are well-suited for applications where thermal management and reliability are essential:

Automotive

- Battery management systems (BMS)

- Electric power steering (EPS)

- Seat controls

- Lighting controls

- Electric water pumps

- Motor drives

- DC-DC converters

Industrial

- Battery management systems (BMS)

- Motor drives

Consumer

- Power tool

- Garden tools

- AI Server & Computing

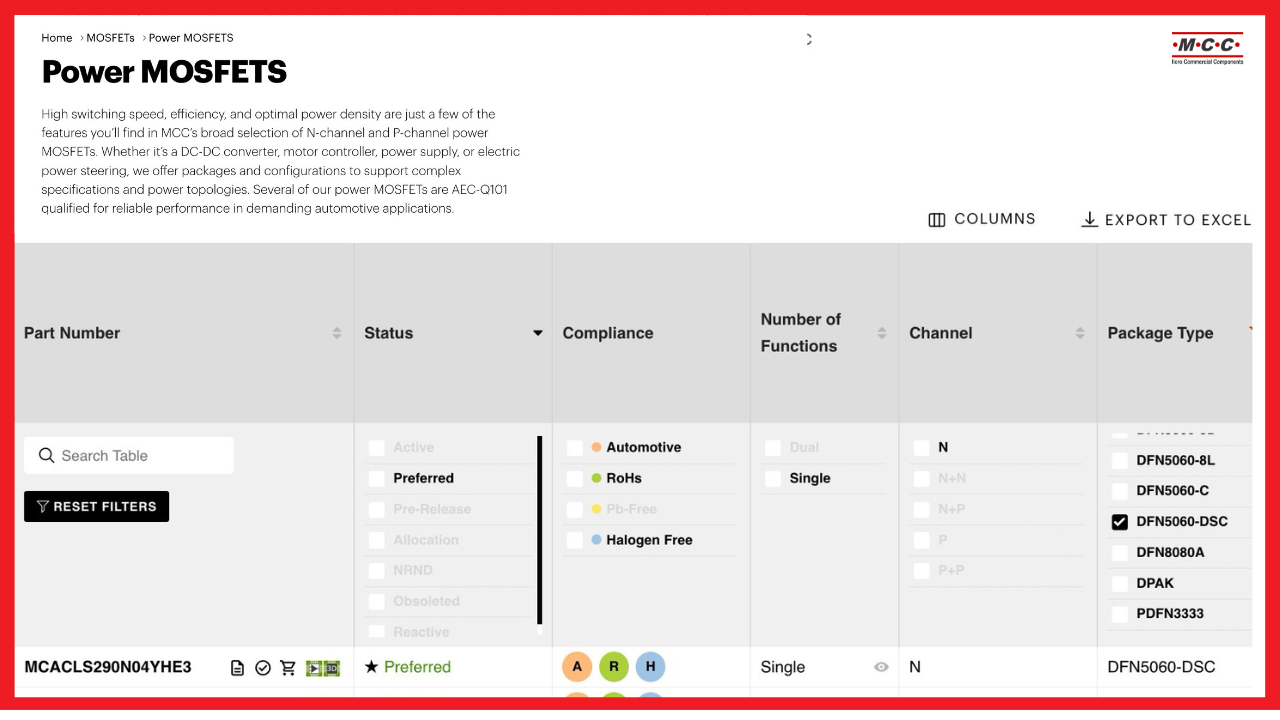

Recommended Dual-Side Cooling Power MOSFETs

Auto-Grade MOSFETs

Highlights: MCACLS290N04YHE3

- Drain-source voltage: 40V

- Low RDS(on): 1.1 mΩ

- Continuous drain current: 290A

- AEC-Q101 qualified

- Split-gate trench (SGT) technology

- Superior overall thermal performance compared to DFN5060 package

- Exceptional top heatsink efficiency

- High power density package

- High junction temperature up to 175℃

- Compact package DFN5060-DSC package (5mm x 6mm)

Power MOSFETS

Highlights: MCACLS330N04YAHE3

- Drain-source voltage: 40V

- Low RDS(on): 1.1 mΩ

- Continuous drain current: 330A

- AEC-Q101 qualified

- Split-gate trench (SGT) technology

- Superior overall thermal performance compared to DFN5060 package

- Exceptional top heatsink efficiency

- High power density package

- High junction temperature up to 175℃

- Compact package DFN5060-DSC package (5mm x 6mm)

.png?width=500&height=500&name=Dual%20Side%20Cooling%20Technology%20in%20DFN%205x6%20Packages%20Next-generation%20thermal%20management%20solutions%20-%20mcc%20semi%20500x500%20-%20micro%20commercial%20components%20(500%20x%20500%20px).png)

You may also be interested in:

Contact MCC for advanced solutions that deliver a competitive edge.

MCC is a manufacturer of high-quality discrete semiconductors to the consumer markets © MCC. All Rights Reserved · 2026